diff --git a/L2 Understading electric vehicless/Different types of motors used in Electric Vehicles.md b/L2 Understading electric vehicless/Different types of motors used in Electric Vehicles.md

index c55d93c..eb50840 100644

--- a/L2 Understading electric vehicless/Different types of motors used in Electric Vehicles.md

+++ b/L2 Understading electric vehicless/Different types of motors used in Electric Vehicles.md

@@ -1,66 +1,67 @@

[Content Suggestions: This content can be broken down into two chapters, and some more content like https://www.youtube.com/watch?v=CWulQ1ZSE3c or

https://youtu.be/bCEiOnuODac?feature=shared can be added in the future]: #

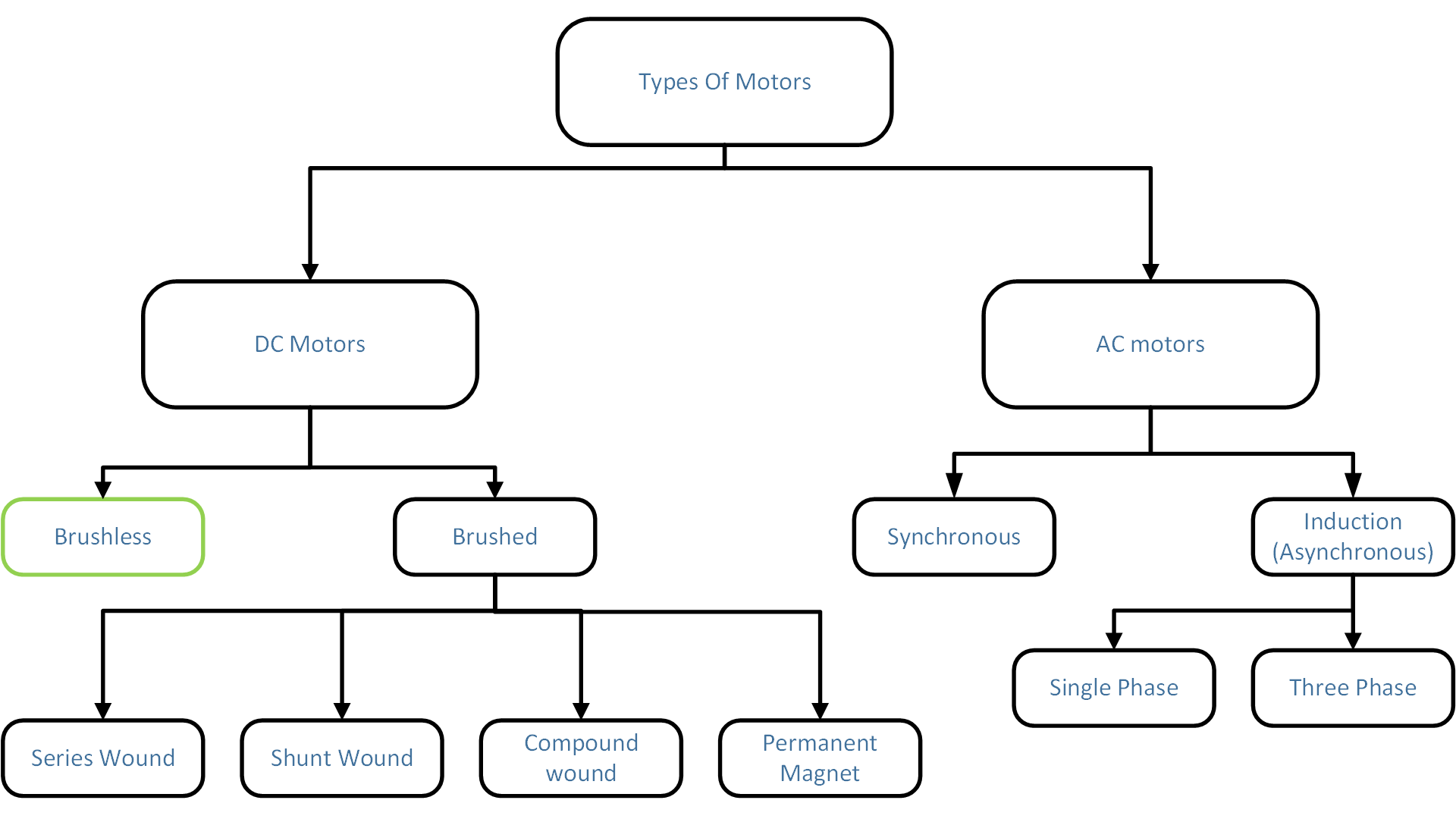

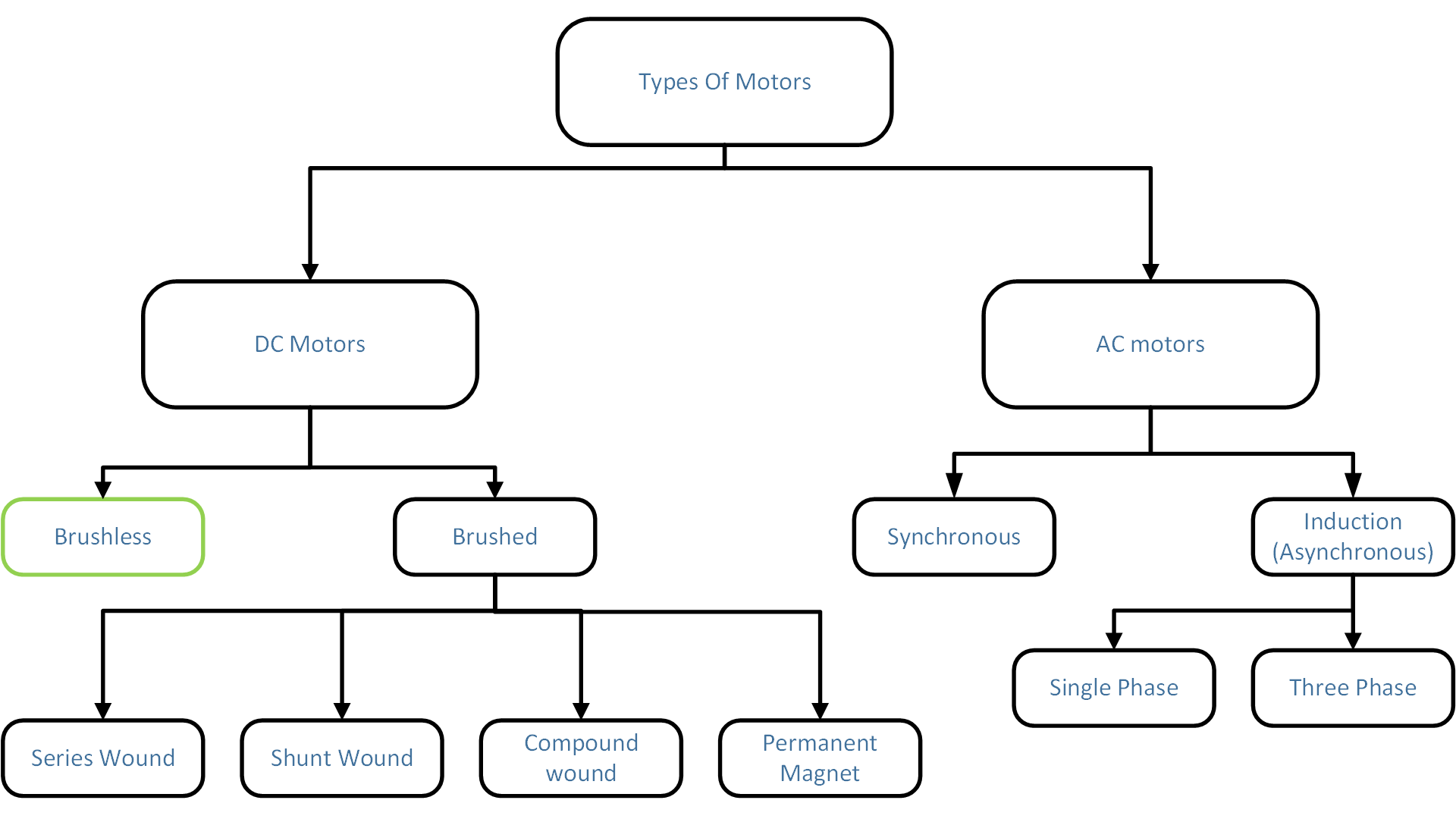

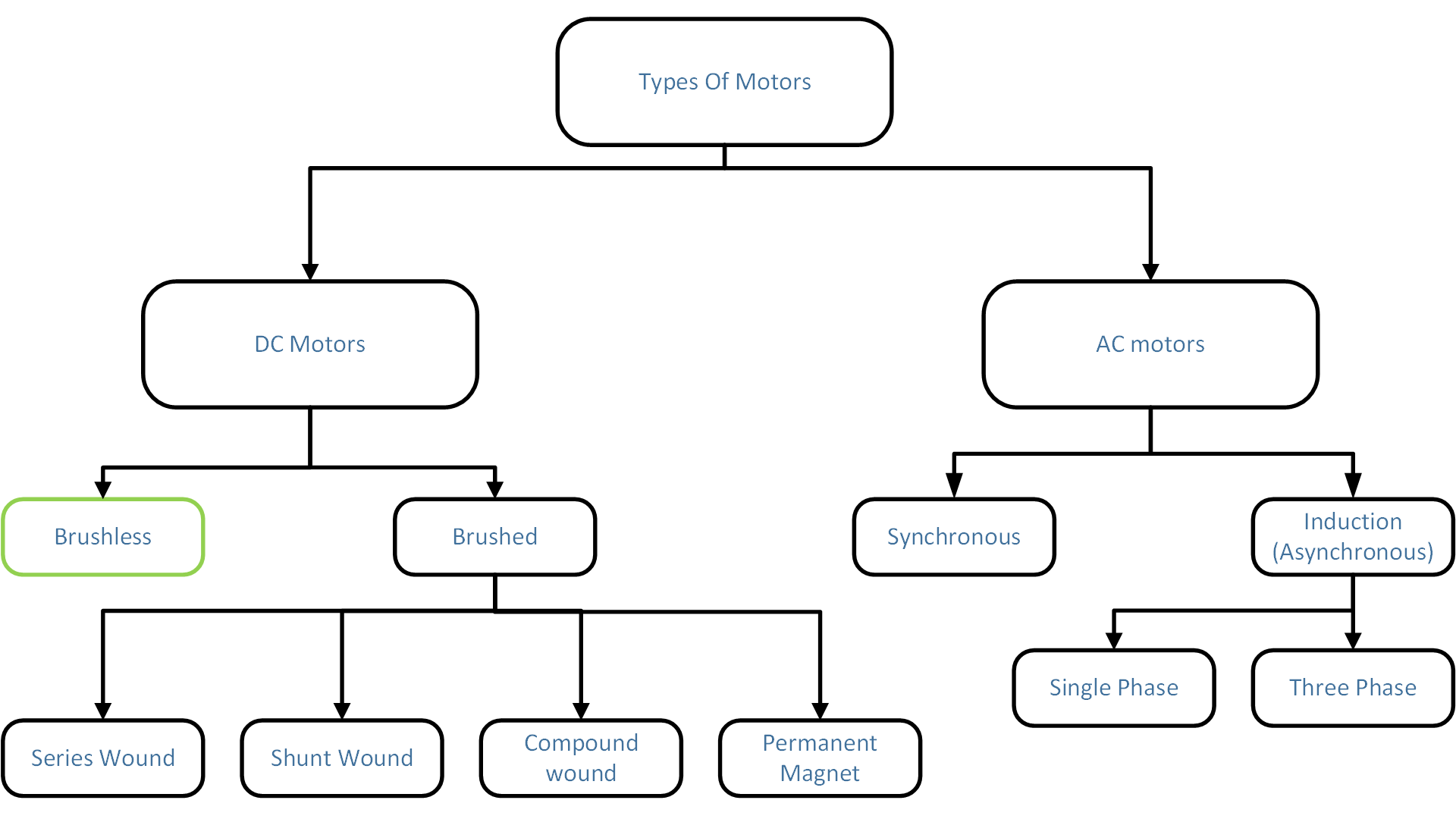

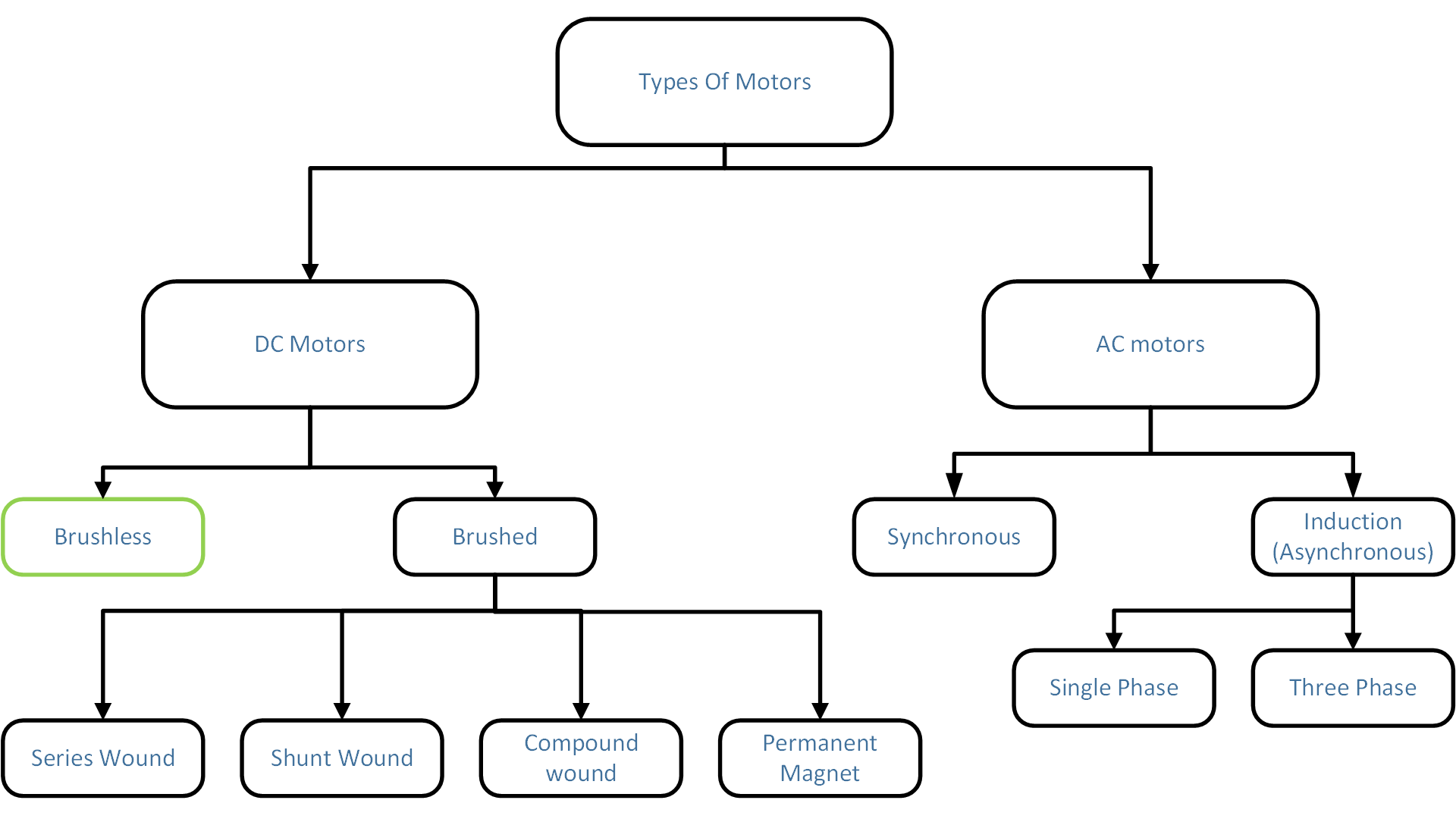

-In the world of internal combustion engines, no two are identical due to various configurations and features. While one might have expected a single best engine type to emerge, the diversity caters to individual needs. This trend extends to electric vehicles, but the options are simpler: **DC motors** and **Induction motors**. We'll focus on Brushless DC motors and AC induction motors for electric vehicles.

+In the world of internal combustion engines, no two are identical due to various configurations and features. One might have expected a single best engine type to emerge, but the diversity caters to individual needs. This trend extends to electric vehicles, but the options are simpler: **DC motors** and **Induction motors**. We'll focus on Brushless DC motors and AC induction motors for electric vehicles.

-But first, what's an electric motor? It's an electromechanical device converting electrical energy to mechanical energy, shaping our modern world. At its core, an electric motor is straightforward: input electricity, and an axle rotates, providing power to a machine. How does this process occur?

+First, let's understand what an electric motor is. It's an electromechanical device converting electrical energy to mechanical energy, shaping our modern world. The basic idea of an electric motor is simple: you input electricity at one end, and an axle (metal rod) rotates at the other end, providing power to drive a machine. But how exactly does this process occur? Exactly how do you convert electricity into movement?

-But first, **let's understand what an electric motor is**.

-A motor is nothing but an electromechanical device that converts electrical energy into mechanical energy. It is because of motors, life is what it is today in the 21st century.

-The basic idea of an electric motor is simple: you put electricity into it at one end, and an axle (metal rod) rotates at the other end, giving you the power to drive a machine of some kind. How does this work in practice? Exactly how do you convert electricity into movement?

+---

----------

Suppose you take a length of ordinary copper wire, make it into a big loop, and lay it between the poles of a powerful, permanent horseshoe magnet. Now, if you connect the two ends of the wire to a battery, the wire will jump up briefly.

-It's amazing when you see this for the first time. It's just like magic! But there's a perfectly scientific explanation. When an electric current starts to creep along a wire, it creates a magnetic field all around it. If you place the wire near a permanent magnet, this temporary magnetic field interacts with the permanent magnet's field. You'll know that two magnets placed near one another either attract or repel. In the same way, the temporary magnetism around the wire attracts or repels the permanent magnetism from the magnet, and that's what causes the wire to jump.

+It's amazing when you see this for the first time. It's just like magic! But there's a perfectly scientific explanation. When an electric current starts to flow along a wire, it creates a magnetic field all around it. If you place the wire near a permanent magnet, this temporary magnetic field interacts with the permanent magnet's field. Just as two magnets placed near one another either attract or repel, the temporary magnetism around the wire attracts or repels the permanent magnetism from the magnet, causing the wire to jump.

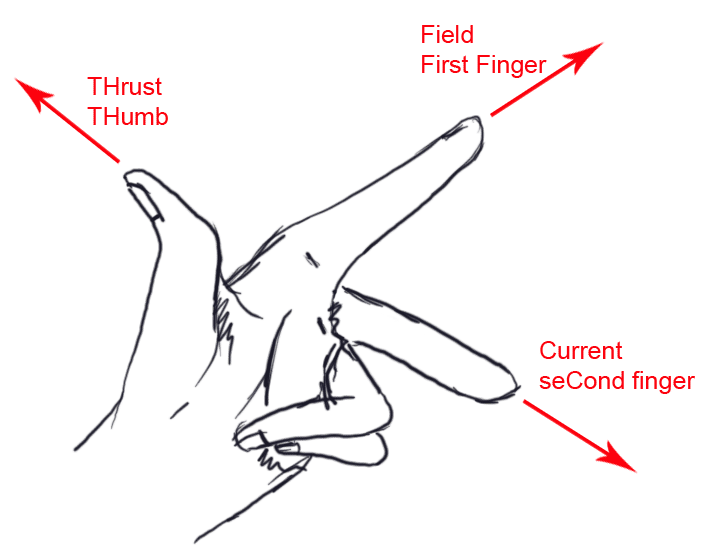

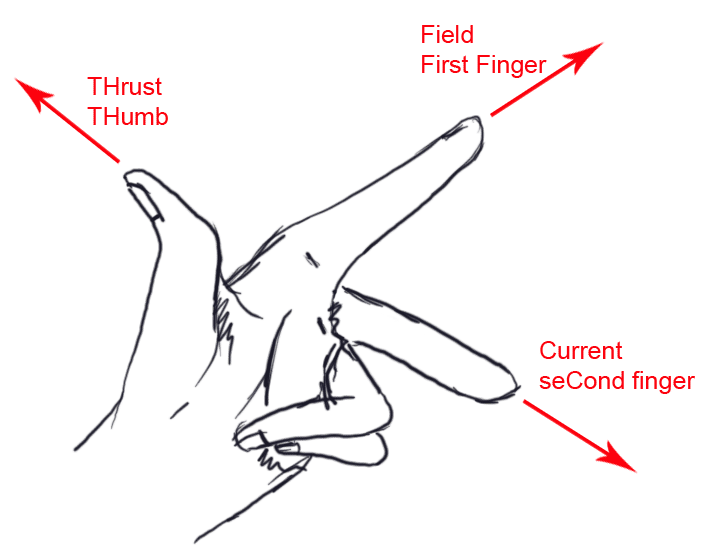

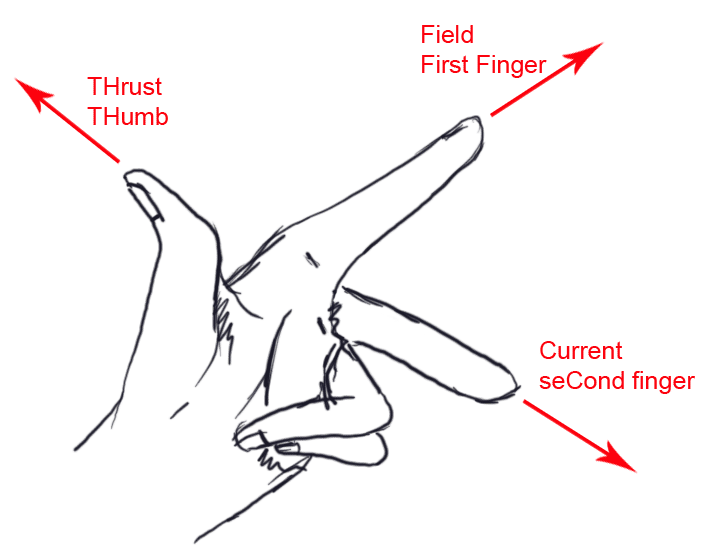

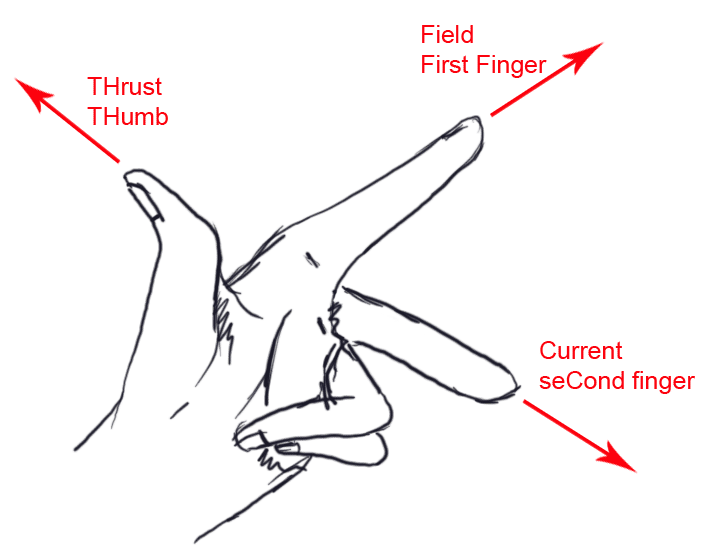

You can figure out the direction in which the wire will jump using a method called **Fleming's Left-Hand Rule**.

-Hold out the thumb, first finger, and second finger of your left hand so all three are at right angles. If you point the second finger in the direction of the current (which flows from the positive to the negative terminal of the battery), and the first finger in the direction of the Field (which flows from the North to the South pole of the magnet), your thumb's will show the direction in which the wire moves.

+1. Hold out the thumb, first finger, and second finger of your left hand so all three are at right angles.

+2. If you point the second finger in the direction of the current (which flows from the positive to the negative terminal of the battery).

+3. Point the first finger in the direction of the _field_ (which flows from the North to the South pole of the magnet), your thumb's will ten indicate the direction in which the wire moves.

-=- Left hand Rule | License: [CC BY-SA 3.0](https://creativecommons.org/licenses/by-sa/3.0/)

-And this is the basic science behind an electric motor. But if we want to turn this amazing scientific discovery into a more practical bit of technology to power our electric bikes and cars, we've got to take it a little bit further.

+And this is the basic science behind an electric motor. However, to turn this scientific discovery into practical technology for powering electric bikes and cars, we need to explore further.

-Don't worry, we will dig deep into all the motor types and their uses in EV 201 after you finish this course.

+Don't worry, we will dive deep into all the motor types and their uses in EV 201 after you finish this course.

-But for now, let's understand the **types of electric motors that are available**, and have a brief look at how they work and what differentiates them.

+For now, let's understand the **types of electric motors** available, and take a brief look at how they work and what differentiates them.

-## Let's have a closer look.

+## Let's have a closer look

-So, what are these two technologies? How do they work? What differentiates them? And what do they have in common? Let’s start with DC brushless drives also known as BLDC motors!

+So, what are these two technologies? How do they work? What differentiates them? And what do they have in common? Let’s start with DC brushless drives, also known as BLDC motors!

-

-It's amazing when you see this for the first time. It's just like magic! But there's a perfectly scientific explanation. When an electric current starts to creep along a wire, it creates a magnetic field all around it. If you place the wire near a permanent magnet, this temporary magnetic field interacts with the permanent magnet's field. You'll know that two magnets placed near one another either attract or repel. In the same way, the temporary magnetism around the wire attracts or repels the permanent magnetism from the magnet, and that's what causes the wire to jump.

+It's amazing when you see this for the first time. It's just like magic! But there's a perfectly scientific explanation. When an electric current starts to flow along a wire, it creates a magnetic field all around it. If you place the wire near a permanent magnet, this temporary magnetic field interacts with the permanent magnet's field. Just as two magnets placed near one another either attract or repel, the temporary magnetism around the wire attracts or repels the permanent magnetism from the magnet, causing the wire to jump.

You can figure out the direction in which the wire will jump using a method called **Fleming's Left-Hand Rule**.

-Hold out the thumb, first finger, and second finger of your left hand so all three are at right angles. If you point the second finger in the direction of the current (which flows from the positive to the negative terminal of the battery), and the first finger in the direction of the Field (which flows from the North to the South pole of the magnet), your thumb's will show the direction in which the wire moves.

+1. Hold out the thumb, first finger, and second finger of your left hand so all three are at right angles.

+2. If you point the second finger in the direction of the current (which flows from the positive to the negative terminal of the battery).

+3. Point the first finger in the direction of the _field_ (which flows from the North to the South pole of the magnet), your thumb's will ten indicate the direction in which the wire moves.

-=- Left hand Rule | License: [CC BY-SA 3.0](https://creativecommons.org/licenses/by-sa/3.0/)

-And this is the basic science behind an electric motor. But if we want to turn this amazing scientific discovery into a more practical bit of technology to power our electric bikes and cars, we've got to take it a little bit further.

+And this is the basic science behind an electric motor. However, to turn this scientific discovery into practical technology for powering electric bikes and cars, we need to explore further.

-Don't worry, we will dig deep into all the motor types and their uses in EV 201 after you finish this course.

+Don't worry, we will dive deep into all the motor types and their uses in EV 201 after you finish this course.

-But for now, let's understand the **types of electric motors that are available**, and have a brief look at how they work and what differentiates them.

+For now, let's understand the **types of electric motors** available, and take a brief look at how they work and what differentiates them.

-## Let's have a closer look.

+## Let's have a closer look

-So, what are these two technologies? How do they work? What differentiates them? And what do they have in common? Let’s start with DC brushless drives also known as BLDC motors!

+So, what are these two technologies? How do they work? What differentiates them? And what do they have in common? Let’s start with DC brushless drives, also known as BLDC motors!

- +

+ -With brushless motors, the rotor includes two or more permanent magnets that generate a DC magnetic field (as seen from the vantage point of the rotor). In turn, this magnetic field enters the stator core (a core made up of thin, stacked laminations) and interacts with currents flowing within the windings to produce a magnetic interaction between the rotor and stator. As the rotor rotates, it is necessary that the magnitude and polarity of the stator currents be continuously varied – and in just the right way - such that the torque remains constant and the conversion of electrical to mechanical energy is done efficiently. The device that provides this current control is called an **inverter or a motor controller**. Without it, brushless motors are useless motors.]

+In brushless motors, the rotor includes two or more permanent magnets that generate a DC magnetic field (as seen from the rotor's perspective). This magnetic field enters the stator core which made up of thin, stacked laminations. The interaction between the magnetic field and the currents flowing within the windings of the stator produces a magnetic interaction between the rotor and stator.

-Working of a BLDC motor

+As the rotor rotates, it is necessary that the magnitude and polarity of the stator currents be continuously varied – and in just the right way - such that the torque remains constant and the conversion of electrical to mechanical energy is done efficiently. The device that provides this current control is called an **inverter or a motor controller**. Without it, brushless motors are useless motors.

-Let's make it much simpler and understand it better by taking the below example, imagine a donkey with a carrot hung in front of its face, the donkey will proceed to follow the carrot constantly.

+## Working of a BLDC motor

-

-With brushless motors, the rotor includes two or more permanent magnets that generate a DC magnetic field (as seen from the vantage point of the rotor). In turn, this magnetic field enters the stator core (a core made up of thin, stacked laminations) and interacts with currents flowing within the windings to produce a magnetic interaction between the rotor and stator. As the rotor rotates, it is necessary that the magnitude and polarity of the stator currents be continuously varied – and in just the right way - such that the torque remains constant and the conversion of electrical to mechanical energy is done efficiently. The device that provides this current control is called an **inverter or a motor controller**. Without it, brushless motors are useless motors.]

+In brushless motors, the rotor includes two or more permanent magnets that generate a DC magnetic field (as seen from the rotor's perspective). This magnetic field enters the stator core which made up of thin, stacked laminations. The interaction between the magnetic field and the currents flowing within the windings of the stator produces a magnetic interaction between the rotor and stator.

-Working of a BLDC motor

+As the rotor rotates, it is necessary that the magnitude and polarity of the stator currents be continuously varied – and in just the right way - such that the torque remains constant and the conversion of electrical to mechanical energy is done efficiently. The device that provides this current control is called an **inverter or a motor controller**. Without it, brushless motors are useless motors.

-Let's make it much simpler and understand it better by taking the below example, imagine a donkey with a carrot hung in front of its face, the donkey will proceed to follow the carrot constantly.

+## Working of a BLDC motor

- +Let's make it much simpler and understand it better by taking the below example, imagine a donkey with a carrot hung in front of its face; the donkey will proceed to follow the carrot constantly.

-Here, regarding our motors, consider the rotating shaft in the center also called as a **rotor** in Figure 1 with a permanent magnet with 2 poles as your **donkey**, and consider the stationary part with the orange coils also called as a **Stator** as your **Carrot**.

+

+Let's make it much simpler and understand it better by taking the below example, imagine a donkey with a carrot hung in front of its face; the donkey will proceed to follow the carrot constantly.

-Here, regarding our motors, consider the rotating shaft in the center also called as a **rotor** in Figure 1 with a permanent magnet with 2 poles as your **donkey**, and consider the stationary part with the orange coils also called as a **Stator** as your **Carrot**.

+ -The orange coils on the stator work as an **electromagnet** that attracts the poles of the permanent magnets present in the rotor in between the stator - see Figure 1.

+Here, regarding our motors, consider the rotating shaft in the center, also called as a **rotor** in Figure 1 with a permanent magnet with 2 poles as your **donkey**, and consider the stationary part with the orange coils also called as a **stator** as your **carrot**.

+

+The orange coils on the stator work as an **electromagnet** that attracts the poles of the permanent magnets present in the rotor in-between the stator - see Figure 1.

The rotor rotates whenever the electromagnets are switched on, and the magnets in-between move towards the electromagnets.

-Now, once the electromagnets attract the magnets on the rotor they need to change its polarity, to push the rotor forward along its rotational path. So that it continues rotating, instead of getting stuck in one position.

+Now, once the electromagnets attract the magnets on the rotor they need to change its polarity, to push the rotor forward along its rotational path so that it continues rotating, instead of getting stuck in one position.

That is basically how a BLDC motor works.

We will learn in-depth about DC motors, BLDC motors and their control as well as building your own primitive motor from scratch in the EV 201 course.

-

-The orange coils on the stator work as an **electromagnet** that attracts the poles of the permanent magnets present in the rotor in between the stator - see Figure 1.

+Here, regarding our motors, consider the rotating shaft in the center, also called as a **rotor** in Figure 1 with a permanent magnet with 2 poles as your **donkey**, and consider the stationary part with the orange coils also called as a **stator** as your **carrot**.

+

+The orange coils on the stator work as an **electromagnet** that attracts the poles of the permanent magnets present in the rotor in-between the stator - see Figure 1.

The rotor rotates whenever the electromagnets are switched on, and the magnets in-between move towards the electromagnets.

-Now, once the electromagnets attract the magnets on the rotor they need to change its polarity, to push the rotor forward along its rotational path. So that it continues rotating, instead of getting stuck in one position.

+Now, once the electromagnets attract the magnets on the rotor they need to change its polarity, to push the rotor forward along its rotational path so that it continues rotating, instead of getting stuck in one position.

That is basically how a BLDC motor works.

We will learn in-depth about DC motors, BLDC motors and their control as well as building your own primitive motor from scratch in the EV 201 course.

- +

+ -=- *Rotating 3-phase magnetic field* | License:

[CC0 1.0 Universal Public Domain Dedication](https://creativecommons.org/publicdomain/zero/1.0/deed.en)

@@ -69,37 +70,37 @@ The arrow in the image above is the north pole of the magnet getting attracted t

Now that we have learned a bit about DC brushless motors, the next type is called an **induction motor**.

-##S A closer look at induction motor drives.

+## A closer look at induction motor drives

-A forerunner of the 3-phase induction motor was invented by Nikola Tesla sometime before 1889. Curiously, the stators for the 3-phase induction motor and the DC brushless motor are virtually identical. Both have three sets of “distributed windings” that are inserted within the stator core. The essential difference between the two machines is with the rotor.

+A forerunner of the 3-phase induction motor was invented by Nikola Tesla sometime before 1889. Curiously, the stators for the 3-phase induction motor and the DC brushless motor are virtually identical. Both have three sets of “distributed windings” that are inserted within the stator core. The essential difference between the two machines is with the _rotor_.

-

-=- *Rotating 3-phase magnetic field* | License:

[CC0 1.0 Universal Public Domain Dedication](https://creativecommons.org/publicdomain/zero/1.0/deed.en)

@@ -69,37 +70,37 @@ The arrow in the image above is the north pole of the magnet getting attracted t

Now that we have learned a bit about DC brushless motors, the next type is called an **induction motor**.

-##S A closer look at induction motor drives.

+## A closer look at induction motor drives

-A forerunner of the 3-phase induction motor was invented by Nikola Tesla sometime before 1889. Curiously, the stators for the 3-phase induction motor and the DC brushless motor are virtually identical. Both have three sets of “distributed windings” that are inserted within the stator core. The essential difference between the two machines is with the rotor.

+A forerunner of the 3-phase induction motor was invented by Nikola Tesla sometime before 1889. Curiously, the stators for the 3-phase induction motor and the DC brushless motor are virtually identical. Both have three sets of “distributed windings” that are inserted within the stator core. The essential difference between the two machines is with the _rotor_.

- +

+ -=- _Components of an induction motor_ | Source: [Robo Blazek](https://commons.wikimedia.org/wiki/File:AM_Klietka.png)

-Lets, look at the different parts of the rotor of an induction motor, from the above image

+Lets look at the different parts of the rotor of an induction motor, from the above image:

-1. Number 1 is the shaft that connects the rotor to the output, this is the main component that is involved in transferring all the torque provided by the rotor to the outside load.

+1. **Shaft:** Connects the rotor to the output; this is the main component that transfers all the torque provided by the rotor to the outside load.

-2. Number 2 is called the Squirrel cage because of its shape, it is involved in producing torque by interacting with the rotating magnetic fields

+2. **Squirrel cage:** Named for its shape, it produces torque by interacting with the rotating magnetic fields.

-

-=- _Components of an induction motor_ | Source: [Robo Blazek](https://commons.wikimedia.org/wiki/File:AM_Klietka.png)

-Lets, look at the different parts of the rotor of an induction motor, from the above image

+Lets look at the different parts of the rotor of an induction motor, from the above image:

-1. Number 1 is the shaft that connects the rotor to the output, this is the main component that is involved in transferring all the torque provided by the rotor to the outside load.

+1. **Shaft:** Connects the rotor to the output; this is the main component that transfers all the torque provided by the rotor to the outside load.

-2. Number 2 is called the Squirrel cage because of its shape, it is involved in producing torque by interacting with the rotating magnetic fields

+2. **Squirrel cage:** Named for its shape, it produces torque by interacting with the rotating magnetic fields.

- +

+ -=- Credit: [el Fantin](https://commons.wikimedia.org/wiki/File:Rotating_Magnetic_Field.gif) | License:

[Creative Commons Attribution-Share Alike 4.0](https://creativecommons.org/licenses/by-sa/4.0/)

-3. Number 3 are the Laminations that help amplify the flux generated by the rotating magnetic fields, helping produce more adequate torque

+3. **Laminations:** Help amplify the flux generated by the rotating magnetic fields, producing more adequate torque.

-4. Number 4 is the Spline shaft, it is basically a textured shaft that helps connect the laminations and the torque producing components to the shaft.

+4. **Spline shaft:** A textured shaft that helps connect the laminations and the torque-producing components to the shaft.

-As you can see, unlike the DC brushless rotor, the induction rotor has no magnets – just stacked steel laminations with buried peripheral conductors that form a “shorted structure.” Currents flowing in the stator windings produce a rotating magnetic field that enters the rotor. In turn, the frequency of this magnetic field as “seen” by the rotor is equal to the difference between the applied electrical frequency and the rotational “frequency” of the rotor itself. Accordingly, an induced voltage exists across the shorted structure that is proportionate to this speed difference between the rotor and electrical frequency. In response to this voltage, currents are produced within the rotor conductors that are approximately proportionate to the voltage, hence the speed difference. Finally, these currents interact with the original magnetic field to produce forces – a component of which is the desired rotor torque.

+As you can see, unlike the DC brushless rotor, the induction rotor has no magnets – just stacked steel laminations with buried peripheral conductors that form a “shorted structure”. Currents flowing in the stator windings produce a rotating magnetic field that enters the rotor. In turn, the frequency of this magnetic field as “seen” by the rotor is equal to the difference between the applied electrical frequency and the rotational "frequency" of the rotor itself. Accordingly, an induced voltage exists across the shorted structure that is proportionate to this speed difference between the rotor and electrical frequency. In response to this voltage, currents are produced within the rotor conductors that are approximately proportionate to the voltage, hence the speed difference. Finally, these currents interact with the original magnetic field to produce forces – a component of which is the desired rotor torque.

When a 3-phase induction motor is connected to utility type 3-phase power, torque is produced at the outset.

The motor can start under load. No inverter is needed. The fact that induction motors are directly compatible with conventional utility power is the main reason for their success. In contrast, a brushless DC motor produces no starting torque when directly connected to fixed frequency utility power. They need the aid of an inverter whose “phase” is maintained in step with the angular position of the rotor.

## AC Induction Motor: To Choose or Not to Choose?

-While 3-phase induction motors have great utility, they also have some severe limitations. They cannot operate from DC; AC is a must. Shaft speed is proportionate to line frequency. Hence, when used with utility power, they are constant speed machines. Finally, when operated from utility power, they have limited starting torque and somewhat limited running peak torque capabilities, when compared to DC type machines.

+While 3-phase induction motors have great utility, they also have some severe limitations. They cannot operate from DC; AC is a must. Shaft speed is proportionate to line frequency. Hence, when used with utility power, they are constant-speed machines. Finally, when operated from utility power, they have limited starting torque and somewhat limited running peak torque capabilities, when compared to DC type machines.

Add an inverter (without any feedback control) and it becomes possible to power an induction machine from a battery or other DC source; variable speed also becomes possible simply by adjusting the inverter frequency. Still, torque performance is low compared with DC machines. Add some feedback loops such that the inverter produces the exact frequency that the motor “desires,” and the induction motor is now capable of competing with DC and DC brushless for vehicle applications.

@@ -107,17 +108,23 @@ Add an inverter (without any feedback control) and it becomes possible to power

## Brushless or Induction?

-Both DC brushless and induction drives use motors having similar stators. Both drives use 3-phase modulating inverters. The only differences are the rotors and the inverter controls. And with digital controllers, the only control differences are with control code. (DC brushless drives require an absolute position sensor, while induction drives require only a speed sensor; these differences are relatively small.)

+Both DC brushless and induction drives use motors having similar stators. Both drives use 3-phase modulating inverters, with the primary differences being in the rotors and the inverter controls. With digital controllers, the control differences are mainly in the control code. (DC brushless drives require an absolute position sensor, while induction drives require only a speed sensor; these differences are relatively small.)

+

+### Differences in Heat Generation and Efficiency

One of the main differences is that much less rotor heat is generated with the DC brushless drive. Rotor cooling is easier and peak point efficiency is generally higher for this drive. The DC brushless drive can also operate at unity power factor, whereas the best power factor for the induction drive is about 85 percent. This means that the peak point energy efficiency for a DC brushless drive will typically be a few percentage points higher than for an induction drive.

-**In an ideal brushless drive**

+### In an ideal brushless drive

The strength of the magnetic field produced by the permanent magnets would be adjustable. When maximum torque is required, especially at low speeds, the magnetic field strength (B) should be maximum – so that inverter and motor currents are maintained at their lowest possible values. This minimizes the I²R (current² resistance) losses and thereby optimizes efficiency. Likewise, when torque levels are low, the B field should be reduced such that eddy and hysteresis losses due to B are also reduced. Ideally, B should be adjusted such that the sum of the eddy, hysteresis, and I² losses is minimized.

Unfortunately, there is no easy way of changing "B" with permanent magnets.

-In contrast, induction machines have no magnets and B fields are “adjustable,” since B is proportionate to V/f (voltage to frequency). This means that at light loads, the inverter can reduce voltage such that magnetic losses are reduced and efficiency is maximized. Thus, the induction machine when operated with a smart inverter has an advantage over a DC brushless machine – magnetic and conduction losses can be traded such that efficiency is optimized. This advantage becomes increasingly important as performance is increased. With DC brushless, as machine size grows, the magnetic losses increase proportionately and part load efficiency drops. With induction, as machine size grows, losses do not necessarily grow. Thus, induction drives may be the favored approach where high-performance is desired; peak efficiency will be a little less than with DC brushless, but average efficiency may be better.

+### Induction Machines and Adjustable B Fields

+

+In contrast, induction machines have no magnets and B fields are “adjustable,” since B is proportionate to V/f (voltage to frequency). This means that at light loads, the inverter can reduce voltage such that magnetic losses are reduced and efficiency is maximized. Thus, the induction machine when operated with a smart inverter has an advantage over a DC brushless machine – magnetic and conduction losses can be traded such that efficiency is optimized. This advantage becomes increasingly important as performance is increased. With DC brushless, as machine size grows, the magnetic losses increase proportionately and part load efficiency drops. With induction, as machine size grows, losses do not necessarily grow. Thus, induction drives may be the favored approach where high performance is desired; peak efficiency will be a little less than with DC brushless, but average efficiency may be better.

+

+### Cost and Handling Considerations

Permanent magnets are expensive. Permanent magnet (PM) rotors are also difficult to handle due to large forces that come into play when anything ferromagnetic gets close to them. This means that induction motors will likely retain a cost advantage over PM machines. Also, due to the field weakening capabilities of induction machines, inverter ratings and costs appear to be lower, especially for high-performance drives. Since spinning induction machines produce little or no voltage when de-excited, they are easier to protect.

@@ -129,10 +136,10 @@ Permanent magnets are expensive. Permanent magnet (PM) rotors are also difficult

#### Advantages:

-- BLDC motors generate much less heat as compared to Induction Motors.

+- Generate much less heat compared to induction motors.

- More powerful, with higher speed ranges, and higher dynamic responses.

- These BLDC motors are therefore suitable for high-speed applications (10,000 rpm or above)

-- Are known for their excellent speed control.

+- Known for their excellent speed control.

#### Disadvantages:

diff --git a/L2 Understading electric vehicless/How do Li-ion batteries in BEVs work.md b/L2 Understading electric vehicless/How do Li-ion batteries in BEVs work.md

index 80df73d..8005644 100644

--- a/L2 Understading electric vehicless/How do Li-ion batteries in BEVs work.md

+++ b/L2 Understading electric vehicless/How do Li-ion batteries in BEVs work.md

@@ -1,4 +1,4 @@

-So until now, we learned about how motors work and how they are vital in propelling our automobile. Now let's have a look at what powers those motors - batteries.

+So until now, we learned about how motors work and how they are vital in propelling our automobile. Now let's have a look at what powers those motors - **Batteries**.

Yes, the same ones in your remote and your laptop.

@@ -11,22 +11,22 @@ Each cell has essentially four components:

4. A separator.

-The four components of Li-ion Battery:

+## The four components of Li-ion Battery

-=- Credit: [el Fantin](https://commons.wikimedia.org/wiki/File:Rotating_Magnetic_Field.gif) | License:

[Creative Commons Attribution-Share Alike 4.0](https://creativecommons.org/licenses/by-sa/4.0/)

-3. Number 3 are the Laminations that help amplify the flux generated by the rotating magnetic fields, helping produce more adequate torque

+3. **Laminations:** Help amplify the flux generated by the rotating magnetic fields, producing more adequate torque.

-4. Number 4 is the Spline shaft, it is basically a textured shaft that helps connect the laminations and the torque producing components to the shaft.

+4. **Spline shaft:** A textured shaft that helps connect the laminations and the torque-producing components to the shaft.

-As you can see, unlike the DC brushless rotor, the induction rotor has no magnets – just stacked steel laminations with buried peripheral conductors that form a “shorted structure.” Currents flowing in the stator windings produce a rotating magnetic field that enters the rotor. In turn, the frequency of this magnetic field as “seen” by the rotor is equal to the difference between the applied electrical frequency and the rotational “frequency” of the rotor itself. Accordingly, an induced voltage exists across the shorted structure that is proportionate to this speed difference between the rotor and electrical frequency. In response to this voltage, currents are produced within the rotor conductors that are approximately proportionate to the voltage, hence the speed difference. Finally, these currents interact with the original magnetic field to produce forces – a component of which is the desired rotor torque.

+As you can see, unlike the DC brushless rotor, the induction rotor has no magnets – just stacked steel laminations with buried peripheral conductors that form a “shorted structure”. Currents flowing in the stator windings produce a rotating magnetic field that enters the rotor. In turn, the frequency of this magnetic field as “seen” by the rotor is equal to the difference between the applied electrical frequency and the rotational "frequency" of the rotor itself. Accordingly, an induced voltage exists across the shorted structure that is proportionate to this speed difference between the rotor and electrical frequency. In response to this voltage, currents are produced within the rotor conductors that are approximately proportionate to the voltage, hence the speed difference. Finally, these currents interact with the original magnetic field to produce forces – a component of which is the desired rotor torque.

When a 3-phase induction motor is connected to utility type 3-phase power, torque is produced at the outset.

The motor can start under load. No inverter is needed. The fact that induction motors are directly compatible with conventional utility power is the main reason for their success. In contrast, a brushless DC motor produces no starting torque when directly connected to fixed frequency utility power. They need the aid of an inverter whose “phase” is maintained in step with the angular position of the rotor.

## AC Induction Motor: To Choose or Not to Choose?

-While 3-phase induction motors have great utility, they also have some severe limitations. They cannot operate from DC; AC is a must. Shaft speed is proportionate to line frequency. Hence, when used with utility power, they are constant speed machines. Finally, when operated from utility power, they have limited starting torque and somewhat limited running peak torque capabilities, when compared to DC type machines.

+While 3-phase induction motors have great utility, they also have some severe limitations. They cannot operate from DC; AC is a must. Shaft speed is proportionate to line frequency. Hence, when used with utility power, they are constant-speed machines. Finally, when operated from utility power, they have limited starting torque and somewhat limited running peak torque capabilities, when compared to DC type machines.

Add an inverter (without any feedback control) and it becomes possible to power an induction machine from a battery or other DC source; variable speed also becomes possible simply by adjusting the inverter frequency. Still, torque performance is low compared with DC machines. Add some feedback loops such that the inverter produces the exact frequency that the motor “desires,” and the induction motor is now capable of competing with DC and DC brushless for vehicle applications.

@@ -107,17 +108,23 @@ Add an inverter (without any feedback control) and it becomes possible to power

## Brushless or Induction?

-Both DC brushless and induction drives use motors having similar stators. Both drives use 3-phase modulating inverters. The only differences are the rotors and the inverter controls. And with digital controllers, the only control differences are with control code. (DC brushless drives require an absolute position sensor, while induction drives require only a speed sensor; these differences are relatively small.)

+Both DC brushless and induction drives use motors having similar stators. Both drives use 3-phase modulating inverters, with the primary differences being in the rotors and the inverter controls. With digital controllers, the control differences are mainly in the control code. (DC brushless drives require an absolute position sensor, while induction drives require only a speed sensor; these differences are relatively small.)

+

+### Differences in Heat Generation and Efficiency

One of the main differences is that much less rotor heat is generated with the DC brushless drive. Rotor cooling is easier and peak point efficiency is generally higher for this drive. The DC brushless drive can also operate at unity power factor, whereas the best power factor for the induction drive is about 85 percent. This means that the peak point energy efficiency for a DC brushless drive will typically be a few percentage points higher than for an induction drive.

-**In an ideal brushless drive**

+### In an ideal brushless drive

The strength of the magnetic field produced by the permanent magnets would be adjustable. When maximum torque is required, especially at low speeds, the magnetic field strength (B) should be maximum – so that inverter and motor currents are maintained at their lowest possible values. This minimizes the I²R (current² resistance) losses and thereby optimizes efficiency. Likewise, when torque levels are low, the B field should be reduced such that eddy and hysteresis losses due to B are also reduced. Ideally, B should be adjusted such that the sum of the eddy, hysteresis, and I² losses is minimized.

Unfortunately, there is no easy way of changing "B" with permanent magnets.

-In contrast, induction machines have no magnets and B fields are “adjustable,” since B is proportionate to V/f (voltage to frequency). This means that at light loads, the inverter can reduce voltage such that magnetic losses are reduced and efficiency is maximized. Thus, the induction machine when operated with a smart inverter has an advantage over a DC brushless machine – magnetic and conduction losses can be traded such that efficiency is optimized. This advantage becomes increasingly important as performance is increased. With DC brushless, as machine size grows, the magnetic losses increase proportionately and part load efficiency drops. With induction, as machine size grows, losses do not necessarily grow. Thus, induction drives may be the favored approach where high-performance is desired; peak efficiency will be a little less than with DC brushless, but average efficiency may be better.

+### Induction Machines and Adjustable B Fields

+

+In contrast, induction machines have no magnets and B fields are “adjustable,” since B is proportionate to V/f (voltage to frequency). This means that at light loads, the inverter can reduce voltage such that magnetic losses are reduced and efficiency is maximized. Thus, the induction machine when operated with a smart inverter has an advantage over a DC brushless machine – magnetic and conduction losses can be traded such that efficiency is optimized. This advantage becomes increasingly important as performance is increased. With DC brushless, as machine size grows, the magnetic losses increase proportionately and part load efficiency drops. With induction, as machine size grows, losses do not necessarily grow. Thus, induction drives may be the favored approach where high performance is desired; peak efficiency will be a little less than with DC brushless, but average efficiency may be better.

+

+### Cost and Handling Considerations

Permanent magnets are expensive. Permanent magnet (PM) rotors are also difficult to handle due to large forces that come into play when anything ferromagnetic gets close to them. This means that induction motors will likely retain a cost advantage over PM machines. Also, due to the field weakening capabilities of induction machines, inverter ratings and costs appear to be lower, especially for high-performance drives. Since spinning induction machines produce little or no voltage when de-excited, they are easier to protect.

@@ -129,10 +136,10 @@ Permanent magnets are expensive. Permanent magnet (PM) rotors are also difficult

#### Advantages:

-- BLDC motors generate much less heat as compared to Induction Motors.

+- Generate much less heat compared to induction motors.

- More powerful, with higher speed ranges, and higher dynamic responses.

- These BLDC motors are therefore suitable for high-speed applications (10,000 rpm or above)

-- Are known for their excellent speed control.

+- Known for their excellent speed control.

#### Disadvantages:

diff --git a/L2 Understading electric vehicless/How do Li-ion batteries in BEVs work.md b/L2 Understading electric vehicless/How do Li-ion batteries in BEVs work.md

index 80df73d..8005644 100644

--- a/L2 Understading electric vehicless/How do Li-ion batteries in BEVs work.md

+++ b/L2 Understading electric vehicless/How do Li-ion batteries in BEVs work.md

@@ -1,4 +1,4 @@

-So until now, we learned about how motors work and how they are vital in propelling our automobile. Now let's have a look at what powers those motors - batteries.

+So until now, we learned about how motors work and how they are vital in propelling our automobile. Now let's have a look at what powers those motors - **Batteries**.

Yes, the same ones in your remote and your laptop.

@@ -11,22 +11,22 @@ Each cell has essentially four components:

4. A separator.

-The four components of Li-ion Battery:

+## The four components of Li-ion Battery

-=- _General discharging Li battery_ | License: [CC BY-SA 4.0](https://creativecommons.org/licenses/by-sa/4.0/)

-## **1. Cathode**

+## 1. Cathode

The cathode plays an important role in determining the characteristics of the battery as the battery’s capacity and voltage are determined by the active material type used for the cathode.

The higher the lithium, the bigger the capacity; and the bigger the potential difference between cathode and anode, the higher the voltage.

The potential difference is small for anode depending on their type but for the cathode, the potential difference is relatively high in general.

As such, the cathode plays a significant role in determining the voltage of the battery.

->“Cathode” determines the capacity and voltage of a Li-ion battery.

+> “Cathode” determines the capacity and voltage of a Li-ion battery.

-## **2. Anode**

+## 2. Anode

The basic function of an anode is to send "electrons" through the wire when the battery is getting discharged or is connected to an appliance.

@@ -38,10 +38,7 @@ and the electrons (e-) separated from lithium ions move along the wire generatin

Because graphite has optimal qualities such as structural stability, low electrochemical reactivity conditions for storing much lithium ions and price, the material is considered suitable to be used for the anode.

-

-

-

-## **3. Electrolyte**

+## 3. Electrolyte

The electrolyte is the medium by which the movement of ions happens!

@@ -64,17 +61,17 @@ Separators are usually made up of synthetic resins such as polyethylene (PE) and

>”Separator”, the absolute barrier between cathode and anode.

-## To recap

+## Recap

- The electrolyte in the center carries positively charged lithium ions from the anode to the cathode and vice versa through the separator.

- The movement of the lithium ions creates free electrons in the anode which creates a charge at the cathode (blue).

- The electric current caused due to the flowing electrons then flows from the cathode through a device being powered to the anode (red).

-- The separator (black) blocks the flow of electrons inside the battery, forcing it to go through the wire connected outside.

+- The separator (black) blocks the flow of electrons inside the battery, forcing it to go through the wire connected outside (external circuit).

-=- _General discharging Li battery_ | License: [CC BY-SA 4.0](https://creativecommons.org/licenses/by-sa/4.0/)

-## **1. Cathode**

+## 1. Cathode

The cathode plays an important role in determining the characteristics of the battery as the battery’s capacity and voltage are determined by the active material type used for the cathode.

The higher the lithium, the bigger the capacity; and the bigger the potential difference between cathode and anode, the higher the voltage.

The potential difference is small for anode depending on their type but for the cathode, the potential difference is relatively high in general.

As such, the cathode plays a significant role in determining the voltage of the battery.

->“Cathode” determines the capacity and voltage of a Li-ion battery.

+> “Cathode” determines the capacity and voltage of a Li-ion battery.

-## **2. Anode**

+## 2. Anode

The basic function of an anode is to send "electrons" through the wire when the battery is getting discharged or is connected to an appliance.

@@ -38,10 +38,7 @@ and the electrons (e-) separated from lithium ions move along the wire generatin

Because graphite has optimal qualities such as structural stability, low electrochemical reactivity conditions for storing much lithium ions and price, the material is considered suitable to be used for the anode.

-

-

-

-## **3. Electrolyte**

+## 3. Electrolyte

The electrolyte is the medium by which the movement of ions happens!

@@ -64,17 +61,17 @@ Separators are usually made up of synthetic resins such as polyethylene (PE) and

>”Separator”, the absolute barrier between cathode and anode.

-## To recap

+## Recap

- The electrolyte in the center carries positively charged lithium ions from the anode to the cathode and vice versa through the separator.

- The movement of the lithium ions creates free electrons in the anode which creates a charge at the cathode (blue).

- The electric current caused due to the flowing electrons then flows from the cathode through a device being powered to the anode (red).

-- The separator (black) blocks the flow of electrons inside the battery, forcing it to go through the wire connected outside.

+- The separator (black) blocks the flow of electrons inside the battery, forcing it to go through the wire connected outside (external circuit).

-=- Source: [U.S. Department of Energy](https://www.energy.gov/science/doe-explainsbatteries)

### Points to remember

-- The negative electrode and positive electrode are capable of storing lithium ions.

+- Both electrodes can store lithium ions.

- Energy is stored and released as lithium ions travel between these electrodes through the electrolyte.

- The negative electrode is generally made from carbon (graphite) and the electrolyte varies from one type of battery to another, but isn't too important in understanding the basic idea of how the battery works.

@@ -84,7 +81,7 @@ Separators are usually made up of synthetic resins such as polyethylene (PE) and

**Now that we know the basic components of a Li-ion Cell, let's understand more what goes on during charging and discharging!**

----

+

## Charging a battery

When the battery is charging up, the lithium-cobalt oxide, positive electrode gives up some of its lithium ions, which move through the electrolyte to the negative, graphite electrode and remain there. The battery takes in and stores energy during this process.

@@ -100,7 +97,7 @@ When the battery is charging up, the lithium-cobalt oxide, positive electrode gi

3. The battery is charged by a potential difference between the two electrodes.

## Discharging a battery

-When the battery is discharging, the lithium ions move back across the electrolyte to the positive electrode, producing the energy that powers the battery. In both cases, electrons flow in the opposite direction to the ions around the outer circuit. Electrons do not flow through the electrolyte: it's effectively an insulating barrier, so far as electrons are concerned.

+During discharging, the lithium ions move back cathode, producing the energy that powers the battery. In both cases, electrons flow in the opposite direction to the ions around the outer circuit. Electrons do not flow through the electrolyte: it's effectively an insulating barrier, so far as electrons are concerned.

-=- Source: [U.S. Department of Energy](https://www.energy.gov/science/doe-explainsbatteries)

### Points to remember

-- The negative electrode and positive electrode are capable of storing lithium ions.

+- Both electrodes can store lithium ions.

- Energy is stored and released as lithium ions travel between these electrodes through the electrolyte.

- The negative electrode is generally made from carbon (graphite) and the electrolyte varies from one type of battery to another, but isn't too important in understanding the basic idea of how the battery works.

@@ -84,7 +81,7 @@ Separators are usually made up of synthetic resins such as polyethylene (PE) and

**Now that we know the basic components of a Li-ion Cell, let's understand more what goes on during charging and discharging!**

----

+

## Charging a battery

When the battery is charging up, the lithium-cobalt oxide, positive electrode gives up some of its lithium ions, which move through the electrolyte to the negative, graphite electrode and remain there. The battery takes in and stores energy during this process.

@@ -100,7 +97,7 @@ When the battery is charging up, the lithium-cobalt oxide, positive electrode gi

3. The battery is charged by a potential difference between the two electrodes.

## Discharging a battery

-When the battery is discharging, the lithium ions move back across the electrolyte to the positive electrode, producing the energy that powers the battery. In both cases, electrons flow in the opposite direction to the ions around the outer circuit. Electrons do not flow through the electrolyte: it's effectively an insulating barrier, so far as electrons are concerned.

+During discharging, the lithium ions move back cathode, producing the energy that powers the battery. In both cases, electrons flow in the opposite direction to the ions around the outer circuit. Electrons do not flow through the electrolyte: it's effectively an insulating barrier, so far as electrons are concerned.

@@ -108,7 +105,7 @@ When the battery is discharging, the lithium ions move back across the electroly

1. A discharge circuit is formed between the anode and the cathode.

2. Lithium ions stored in the anode move to the cathode.

-3. Energy is used.

+3. Energy is released.

## Important points to remember

@@ -121,11 +118,13 @@ When the battery is discharging, the lithium ions move back across the electroly

- Avoid heat, which degrades the batteries.

+## Understanding C Rate

+

- Electrical current is measured in amperes, or simply amps. But the impact of one ampere of current from a small battery cell is quite different from the impact of one ampere of current from a large battery cell. Hence a relative measure of electrical current is used to scale the size of a battery cell, and this relative measure is known as the **C rate**.

- * The C rate of a battery cell is the level of constant current charge or discharge that the cell can sustain for one hour of time.

+ - The C rate of a battery cell is the level of constant current charge or discharge that the cell can sustain for one hour of time.

- * For example, a cell having a capacity of ` 20 ampere hours (or 20AH)` should be able to deliver 20 amperes of current for one hour or two amperes of current for 10 hours.

+ - For example, a cell having a capacity of ` 20 ampere hours (or 20AH)` should be able to deliver 20 amperes of current for one hour or two amperes of current for 10 hours.

`20 Ampere-Hour` = `20 Amperes` x `1 hour` **or** `2 Amperes` x `10

hours`

@@ -146,6 +145,7 @@ Now, for the battery we have selected, imagine that the maximum current the batt

Now, we know

+

=> `Battery capacity x C rating = Output current`

=> `2500 x C Rating = 20,000 milli-amperes`

@@ -154,4 +154,4 @@ Now, we know

=> `C rating = 8`

-Which means, the `Peak C rating is 8`, and the `continuous C Rating is 0.2` ( from Page 3, point no 3.1)

+Which means, the `Peak C rating is 8`, and the `Continuous C rating is 0.2` ( from Page 3, point no 3.1)

\ No newline at end of file

diff --git a/L2 Understading electric vehicless/Identifying core and secondary parts of a Battery Electric Vehicle (BEV).md b/L2 Understading electric vehicless/Identifying core and secondary parts of a Battery Electric Vehicle (BEV).md

index 5513d8d..6261275 100644

--- a/L2 Understading electric vehicless/Identifying core and secondary parts of a Battery Electric Vehicle (BEV).md

+++ b/L2 Understading electric vehicless/Identifying core and secondary parts of a Battery Electric Vehicle (BEV).md

@@ -1,6 +1,6 @@

Having explored the diverse categories of electric vehicles and their types, let's now conduct an in-depth examination of the composition of a battery electric vehicle (BEV).

-In contrast to traditional internal combustion engine vehicles, **BEVs** are characterized by their simplicity and user-friendly operation. The fundamental powertrain architecture of a BEV comprises a high-voltage battery, an electric motor equipped with a power electronics controller, and a single-speed gearbox. To differentiate them from Hybrid Electric Vehicles (HEVs), which combine an internal combustion engine with an electric motor, BEVs are often referred to as **pure electric vehicles**.

+Battery Electric Vehicles **(BEVs)** are simpler and more user-friendly than traditional internal combustion engine vehicles. The fundamental powertrain architecture of a BEV includes a high-voltage battery, an electric motor with a power electronics controller, and a single-speed gearbox. Unlike Hybrid Electric Vehicles (HEVs) that combine an internal combustion engine with an electric motor, BEVs, also known as **pure electric vehicles**, rely solely on electric power.

For now, our focus will be exclusively on BEVs and their components, specifically focusing in on the powertrain aspect of these electric vehicles.

@@ -8,17 +8,19 @@ For now, our focus will be exclusively on BEVs and their components, specificall

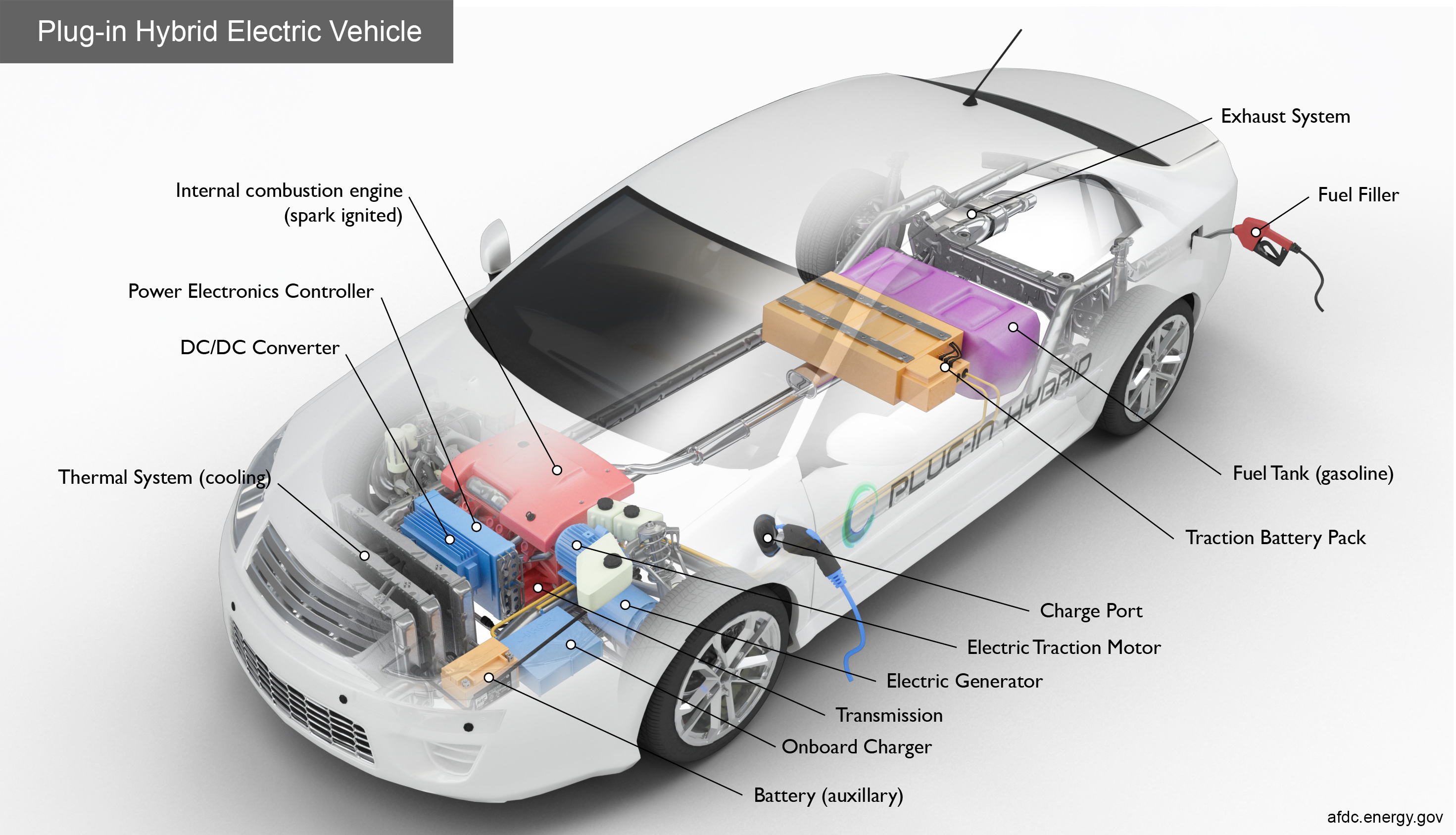

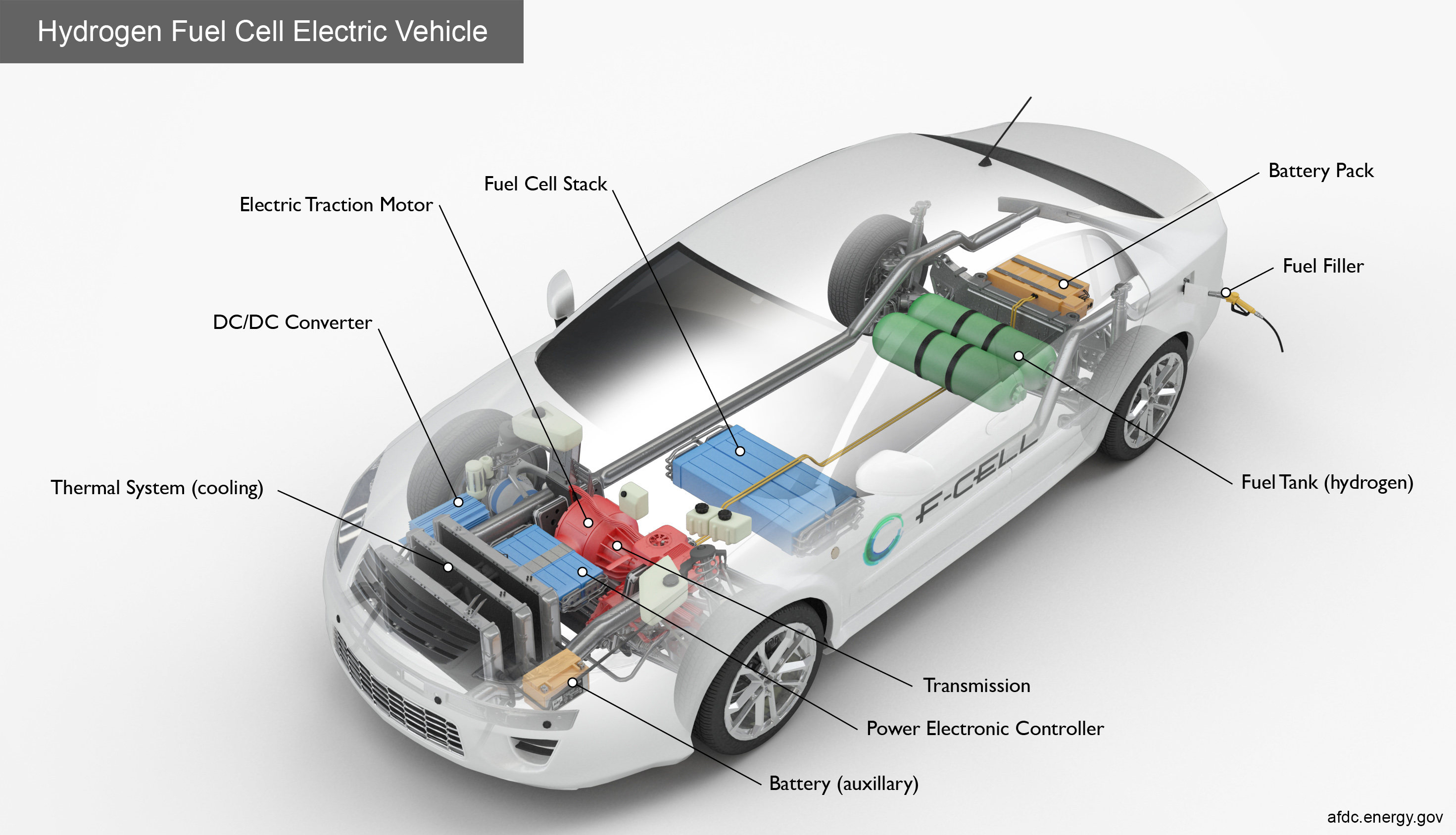

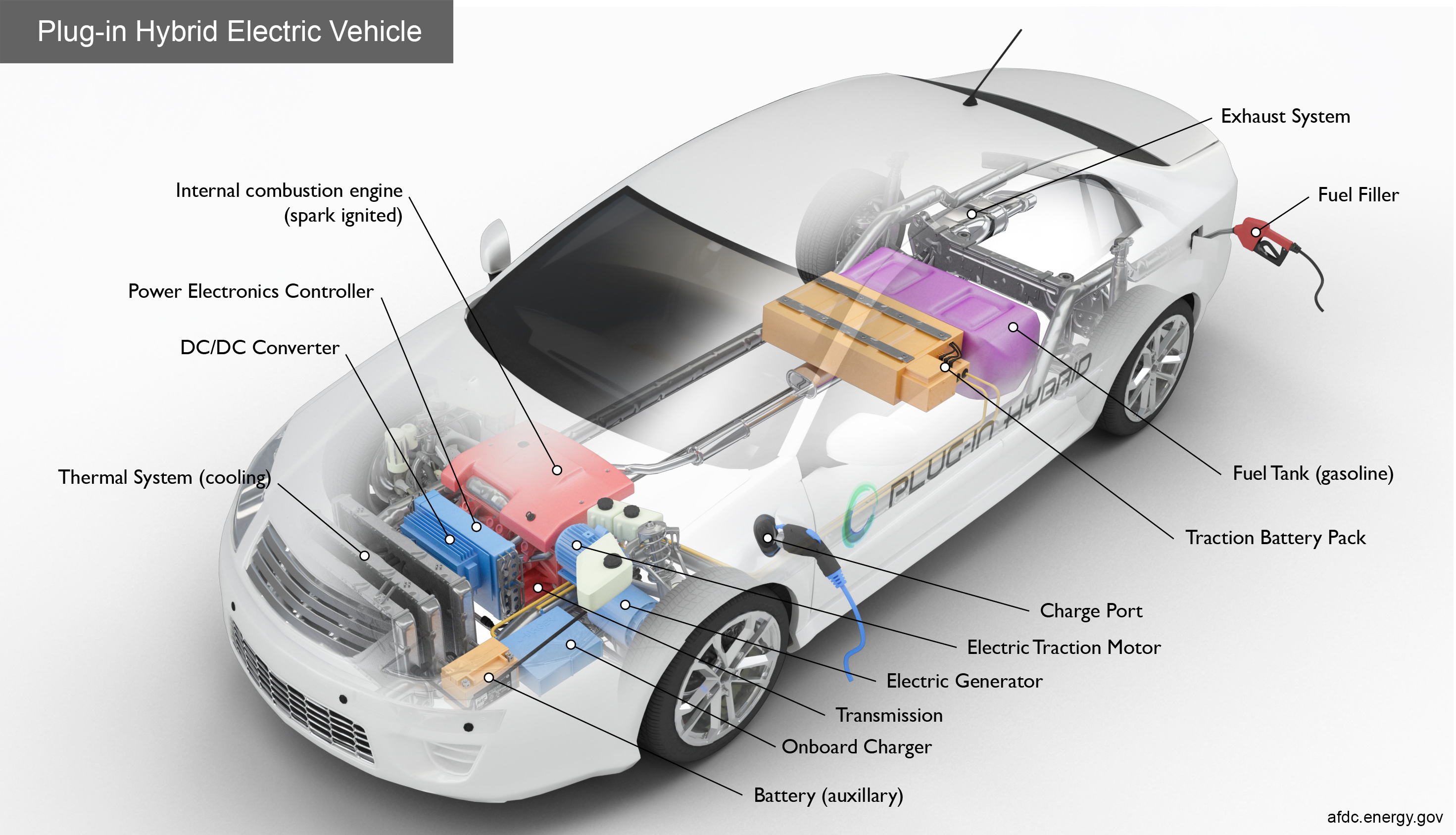

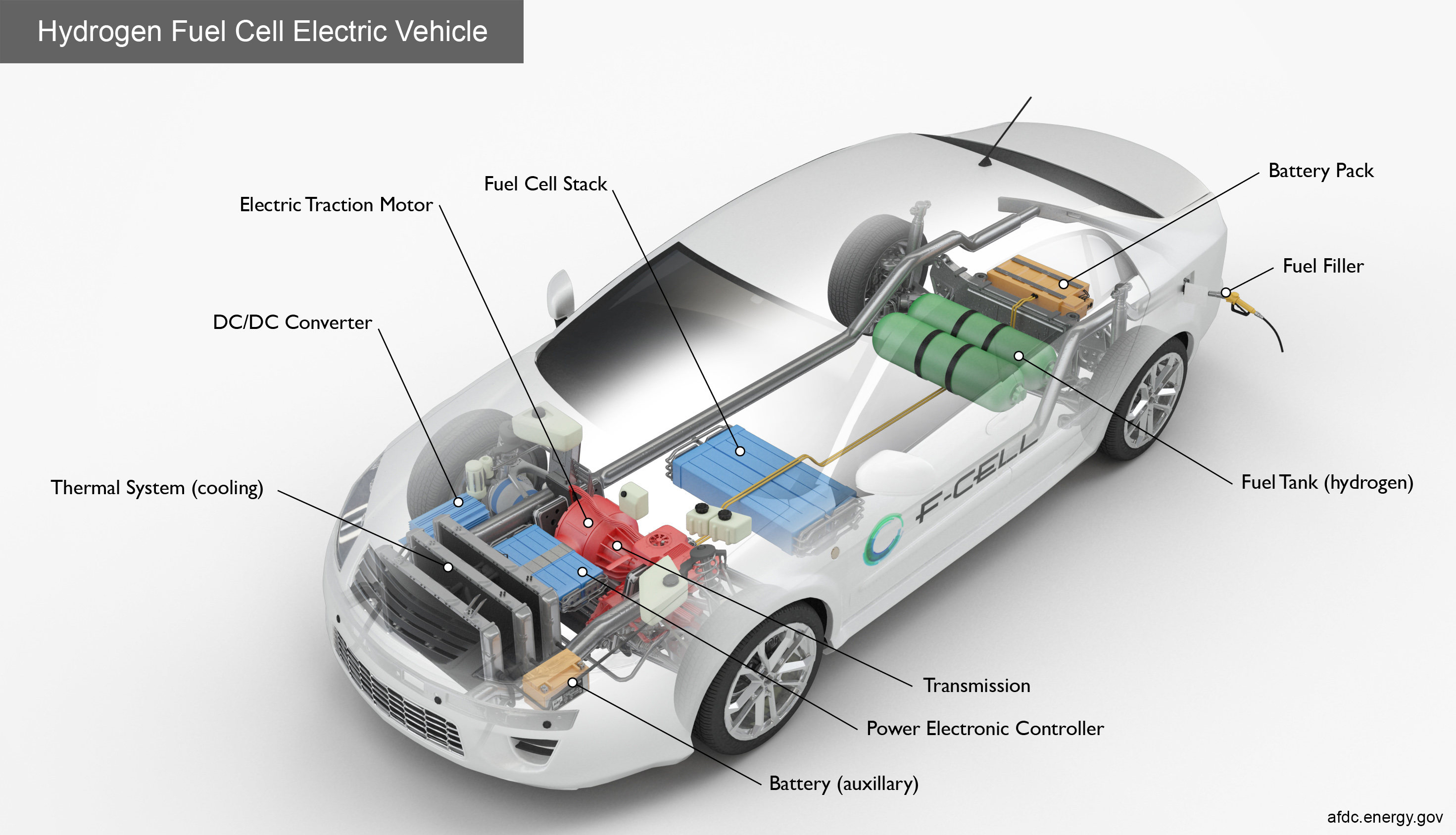

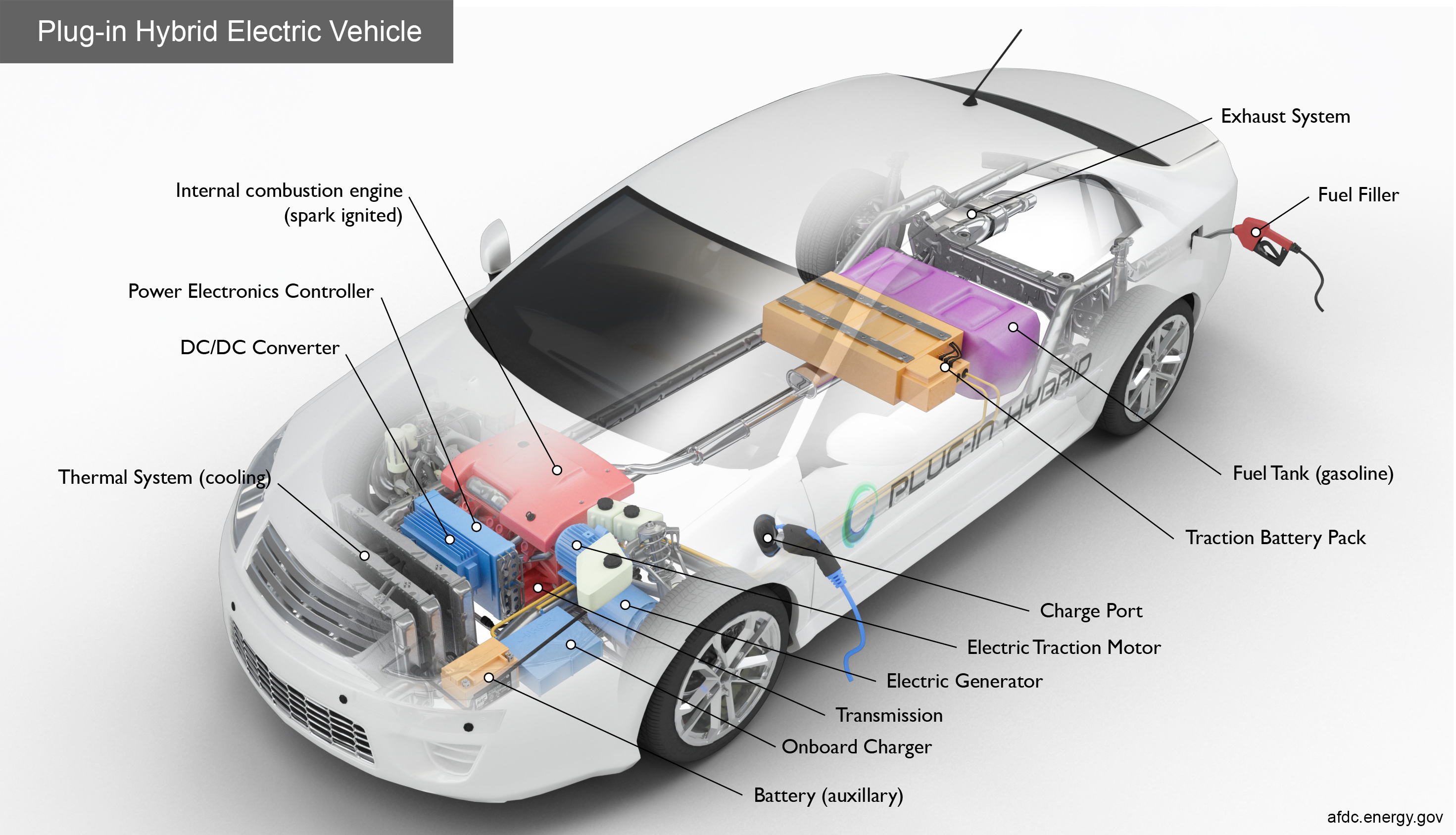

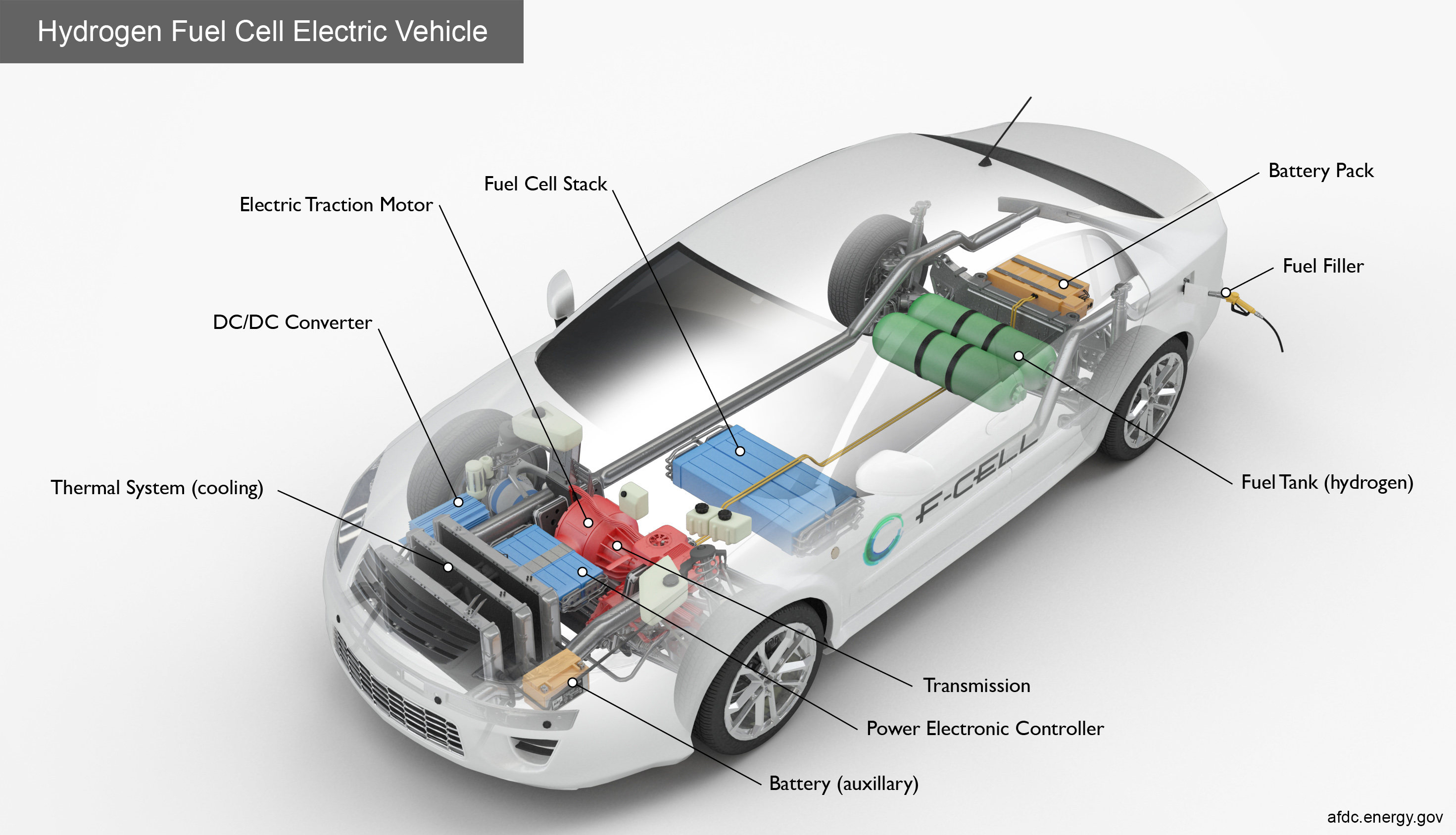

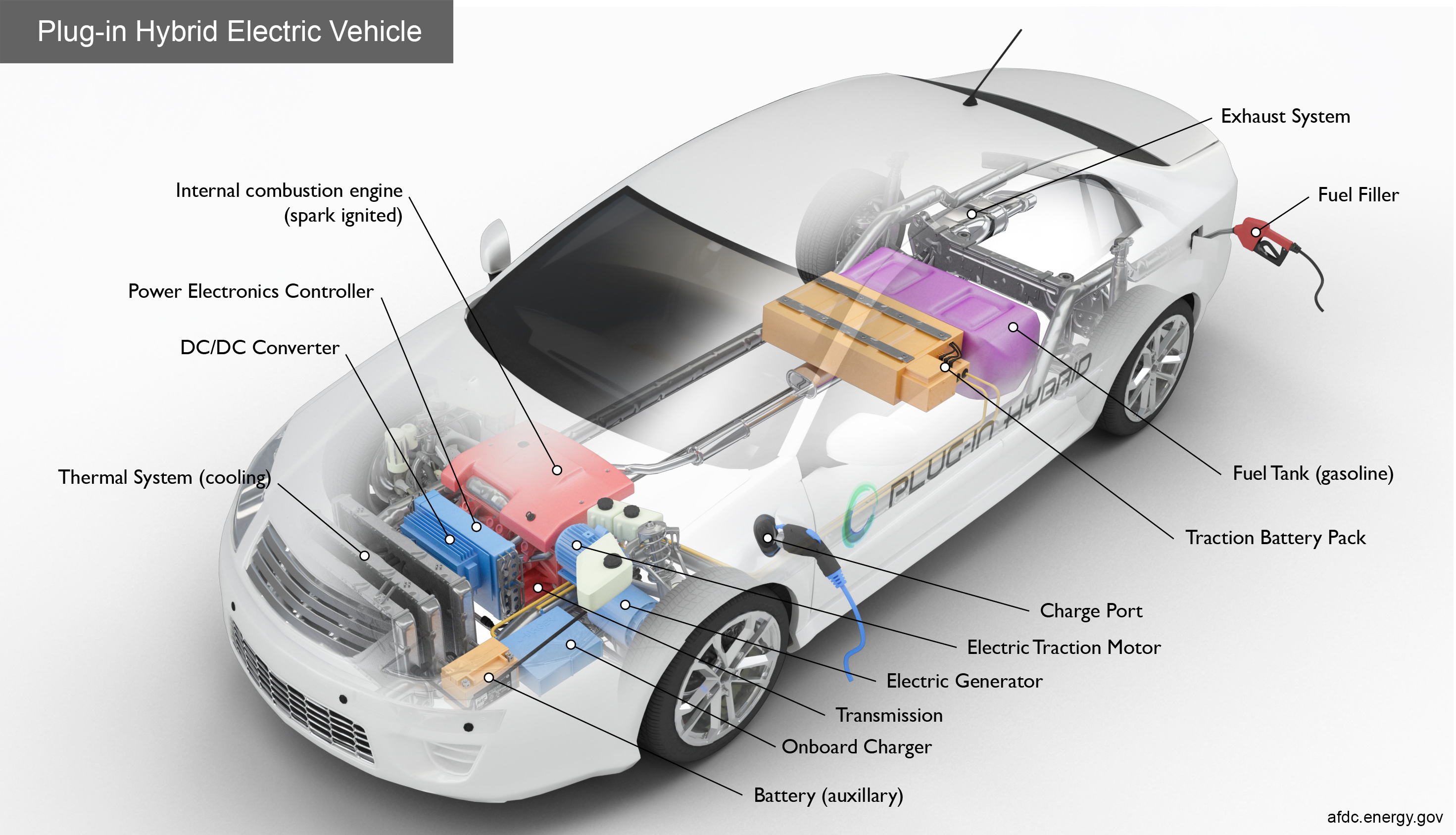

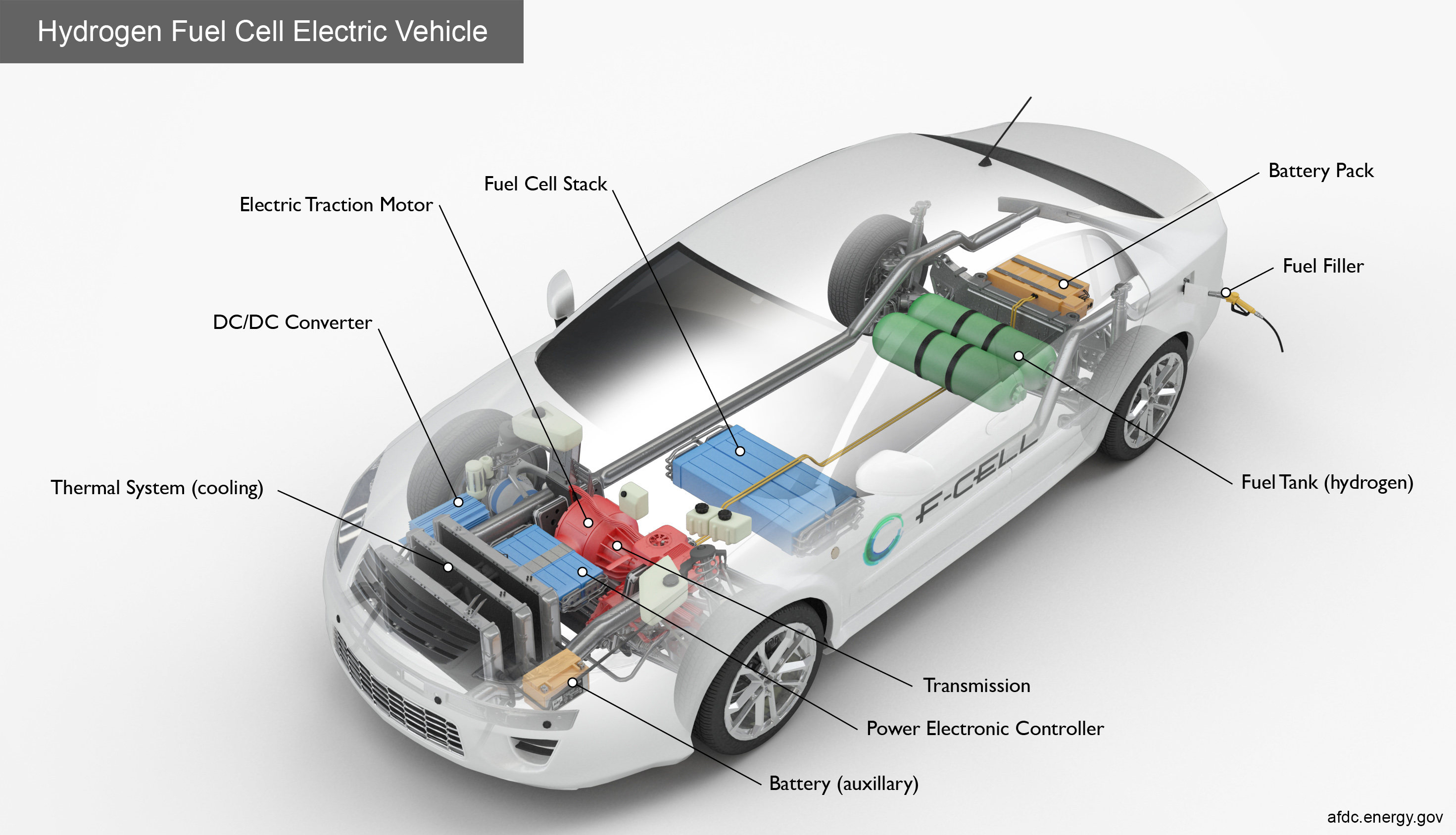

-=- Source: [U.S. Department of Energy](https://afdc.energy.gov/vehicles/how-do-hybrid-electric-cars-work)

-There are multitude of vehicle types in BEV's - here's a list.

+## Types of BEVs

-- **Neighbourhood electric vehicles**: small vehicles, very low range (less than 25 km)

-- **City electric vehicles**: small vehicles, low range (less than 50 km)

-- **Performance battery-electric vehicles**: these are the equivalent of the classic passenger vehicles, with the range between 100 and 600 km

+BEVs come in various types, including:

+

+- **Neighbourhood Electric Vehicles**: Small vehicles, very low range (less than 25 km)

+- **City Electric Vehicles**: Small vehicles, low range (less than 50 km)

+- **Performance Battery-Electric Vehicles**: Comparable to classic passenger vehicles with a range between 100 and 600 km.

Most of the BEV architecture have the powertrain on the front axle and the high voltage battery in the floor, between the front and rear axle. This configuration gives plenty of volume for the passenger area and boot/trunk.

The high voltage battery, being the heaviest electric component of the vehicle, is positioned very low, in the body floor. This gives another advantage, a very low centre of gravity, which improves the overall stability of the vehicle.

-Here is an example of a Jaguar I-pace Electric car, completely stripped. You can see the inner battery placements and motor placements.

+Here's an example of a Jaguar I-pace Electric car, completely stripped. You can see the inner battery placements and motor placements.

@@ -27,39 +29,39 @@ Here is an example of a Jaguar I-pace Electric car, completely stripped. You can

-=- Source: [New Jaguar I-Pace’s battery electric vehicle technology at a glance](https://www.autocar.co.uk/car-news/motor-shows-la-motor-show/new-jaguar-i-pace%E2%80%99s-battery-electric-vehicle-technology-glance) ([License](https://media.jaguarlandrover.com/user-licence))

-## A. The Batteries (The storage component)

+## A. The Batteries (Storage Component)

@@ -108,7 +105,7 @@ When the battery is discharging, the lithium ions move back across the electroly

1. A discharge circuit is formed between the anode and the cathode.

2. Lithium ions stored in the anode move to the cathode.

-3. Energy is used.

+3. Energy is released.

## Important points to remember

@@ -121,11 +118,13 @@ When the battery is discharging, the lithium ions move back across the electroly

- Avoid heat, which degrades the batteries.

+## Understanding C Rate

+

- Electrical current is measured in amperes, or simply amps. But the impact of one ampere of current from a small battery cell is quite different from the impact of one ampere of current from a large battery cell. Hence a relative measure of electrical current is used to scale the size of a battery cell, and this relative measure is known as the **C rate**.

- * The C rate of a battery cell is the level of constant current charge or discharge that the cell can sustain for one hour of time.

+ - The C rate of a battery cell is the level of constant current charge or discharge that the cell can sustain for one hour of time.

- * For example, a cell having a capacity of ` 20 ampere hours (or 20AH)` should be able to deliver 20 amperes of current for one hour or two amperes of current for 10 hours.

+ - For example, a cell having a capacity of ` 20 ampere hours (or 20AH)` should be able to deliver 20 amperes of current for one hour or two amperes of current for 10 hours.

`20 Ampere-Hour` = `20 Amperes` x `1 hour` **or** `2 Amperes` x `10

hours`

@@ -146,6 +145,7 @@ Now, for the battery we have selected, imagine that the maximum current the batt

Now, we know

+

=> `Battery capacity x C rating = Output current`

=> `2500 x C Rating = 20,000 milli-amperes`

@@ -154,4 +154,4 @@ Now, we know

=> `C rating = 8`

-Which means, the `Peak C rating is 8`, and the `continuous C Rating is 0.2` ( from Page 3, point no 3.1)

+Which means, the `Peak C rating is 8`, and the `Continuous C rating is 0.2` ( from Page 3, point no 3.1)

\ No newline at end of file

diff --git a/L2 Understading electric vehicless/Identifying core and secondary parts of a Battery Electric Vehicle (BEV).md b/L2 Understading electric vehicless/Identifying core and secondary parts of a Battery Electric Vehicle (BEV).md

index 5513d8d..6261275 100644

--- a/L2 Understading electric vehicless/Identifying core and secondary parts of a Battery Electric Vehicle (BEV).md

+++ b/L2 Understading electric vehicless/Identifying core and secondary parts of a Battery Electric Vehicle (BEV).md

@@ -1,6 +1,6 @@

Having explored the diverse categories of electric vehicles and their types, let's now conduct an in-depth examination of the composition of a battery electric vehicle (BEV).

-In contrast to traditional internal combustion engine vehicles, **BEVs** are characterized by their simplicity and user-friendly operation. The fundamental powertrain architecture of a BEV comprises a high-voltage battery, an electric motor equipped with a power electronics controller, and a single-speed gearbox. To differentiate them from Hybrid Electric Vehicles (HEVs), which combine an internal combustion engine with an electric motor, BEVs are often referred to as **pure electric vehicles**.

+Battery Electric Vehicles **(BEVs)** are simpler and more user-friendly than traditional internal combustion engine vehicles. The fundamental powertrain architecture of a BEV includes a high-voltage battery, an electric motor with a power electronics controller, and a single-speed gearbox. Unlike Hybrid Electric Vehicles (HEVs) that combine an internal combustion engine with an electric motor, BEVs, also known as **pure electric vehicles**, rely solely on electric power.

For now, our focus will be exclusively on BEVs and their components, specifically focusing in on the powertrain aspect of these electric vehicles.

@@ -8,17 +8,19 @@ For now, our focus will be exclusively on BEVs and their components, specificall

-=- Source: [U.S. Department of Energy](https://afdc.energy.gov/vehicles/how-do-hybrid-electric-cars-work)

-There are multitude of vehicle types in BEV's - here's a list.

+## Types of BEVs

-- **Neighbourhood electric vehicles**: small vehicles, very low range (less than 25 km)

-- **City electric vehicles**: small vehicles, low range (less than 50 km)

-- **Performance battery-electric vehicles**: these are the equivalent of the classic passenger vehicles, with the range between 100 and 600 km

+BEVs come in various types, including:

+

+- **Neighbourhood Electric Vehicles**: Small vehicles, very low range (less than 25 km)

+- **City Electric Vehicles**: Small vehicles, low range (less than 50 km)

+- **Performance Battery-Electric Vehicles**: Comparable to classic passenger vehicles with a range between 100 and 600 km.

Most of the BEV architecture have the powertrain on the front axle and the high voltage battery in the floor, between the front and rear axle. This configuration gives plenty of volume for the passenger area and boot/trunk.

The high voltage battery, being the heaviest electric component of the vehicle, is positioned very low, in the body floor. This gives another advantage, a very low centre of gravity, which improves the overall stability of the vehicle.

-Here is an example of a Jaguar I-pace Electric car, completely stripped. You can see the inner battery placements and motor placements.

+Here's an example of a Jaguar I-pace Electric car, completely stripped. You can see the inner battery placements and motor placements.

@@ -27,39 +29,39 @@ Here is an example of a Jaguar I-pace Electric car, completely stripped. You can

-=- Source: [New Jaguar I-Pace’s battery electric vehicle technology at a glance](https://www.autocar.co.uk/car-news/motor-shows-la-motor-show/new-jaguar-i-pace%E2%80%99s-battery-electric-vehicle-technology-glance) ([License](https://media.jaguarlandrover.com/user-licence))

-## A. The Batteries (The storage component)

+## A. The Batteries (Storage Component)

Image 3 - Schematic build-up of an automotive battery system

Let's take a look at the main component of an EV, i.e. the battery or the storage component.

->We use the word "storage component" here because electric vehicles can either be powered by batteries or via hydrogen fuel cells and both of these store energy in the vehicle.

+> We use the word "storage component" here because electric vehicles can either be powered by batteries or via hydrogen fuel cells and both of these store energy in the vehicle.

The energy storage component in a pure battery electric vehicle is the high voltage (HV) battery. The nominal voltage is, in most of the cases, between 360 and 450 V. A BEV has also a low voltage battery, the usual 12 V battery, which is used as a power supply for the auxiliary equipment (lightning, multimedia, etc.).

The battery is the key component of the EVs because:

-* The range of the vehicle depends almost entirely on the HV battery,

-* It is the heaviest electrical component,

-* It is the most expensive electrical component.

+- The range of the vehicle depends almost entirely on the HV battery.

+- It is the heaviest electrical component.

+- It is the most expensive electrical component.

- >Various types of high voltage batteries exist, with their chemistry serving as the primary distinguishing factor. Among the most common, high voltage (HV) batteries used in Battery Electric Vehicles (BEVs) are the lithium-ion batteries. Furthermore, lithium-ion batteries come in various iterations, each with its own distinctive characteristics.

+ > Various types of high voltage batteries exist, with their chemistry serving as the primary distinguishing factor. Among the most common, high voltage (HV) batteries used in Battery Electric Vehicles (BEVs) are the lithium-ion batteries. Furthermore, lithium-ion batteries come in various iterations, each with its own distinctive characteristics.

> - Metal-oxides (e.g. Lithium Manganese Oxide, LiMn2O2)

> - Phosphates (e.g. Lithium Iron Phosphate, LiFePO4)

**Usually in automotive applications, phosphate lithium-ion batteries are more suitable because they are safer in terms of chemical and thermal hazards.**

-#### The Battery Management System

+## The Battery Management System

Battery Management Systems are the brains behind battery packs. They manage the output, charging and discharging, and provide notifications on the status of the battery pack. They also provide critical safeguards to protect the batteries from damage.

A battery pack usually consists of several individual cells that work together in combination. Ideally, all the cells in a battery pack should be kept at the same state of charge. If the cells go out of balance, individual cells can get stressed and lead to premature charge termination and a reduction in the overall life of the battery.

-The cell balancers of the battery management system, extend the life of the battery by preventing this imbalance of charge in individual cells from occurring.

+The cell balancers of the battery management system, extend the life of the battery by preventing this imbalance of charge in individual cells.

The second most important function performed by a battery management system is **energy management**.

-The key to energy management is **coulomb counting.** For example, if you have 5 people in a room and 2 people leave, you're left with 3. If 3 more people enter, you now have 6 people in the room. If the room has a capacity of 10 people, with 6 people inside, the room is 60% full. A battery management system tracks this capacity. This state of charge is communicated to the user electronically through a digital bus.

+The key to energy management is **coulomb counting**. For example, if you have 5 people in a room and 2 people leave, you're left with 3. If 3 more people enter, you now have 6 people in the room. If the room has a capacity of 10 people, with 6 people inside, the room is 60% full. A battery management system tracks this capacity. This state of charge is communicated to the user electronically through a digital bus.

Battery management systems for smaller electric vehicles also include an embedded charger consisting of a control device, an inductor (which is an energy storage device), and a discharger. The control device manages the charging algorithm.

@@ -76,9 +78,9 @@ Looking at Image 3, we see the complete powertrain of an electric vehicle.

3. Rotor (Part of a motor) - *Shown in Image 5*

4. Single-speed gearbox and differential.

-# Power electronic controller

+## Power electronic controller

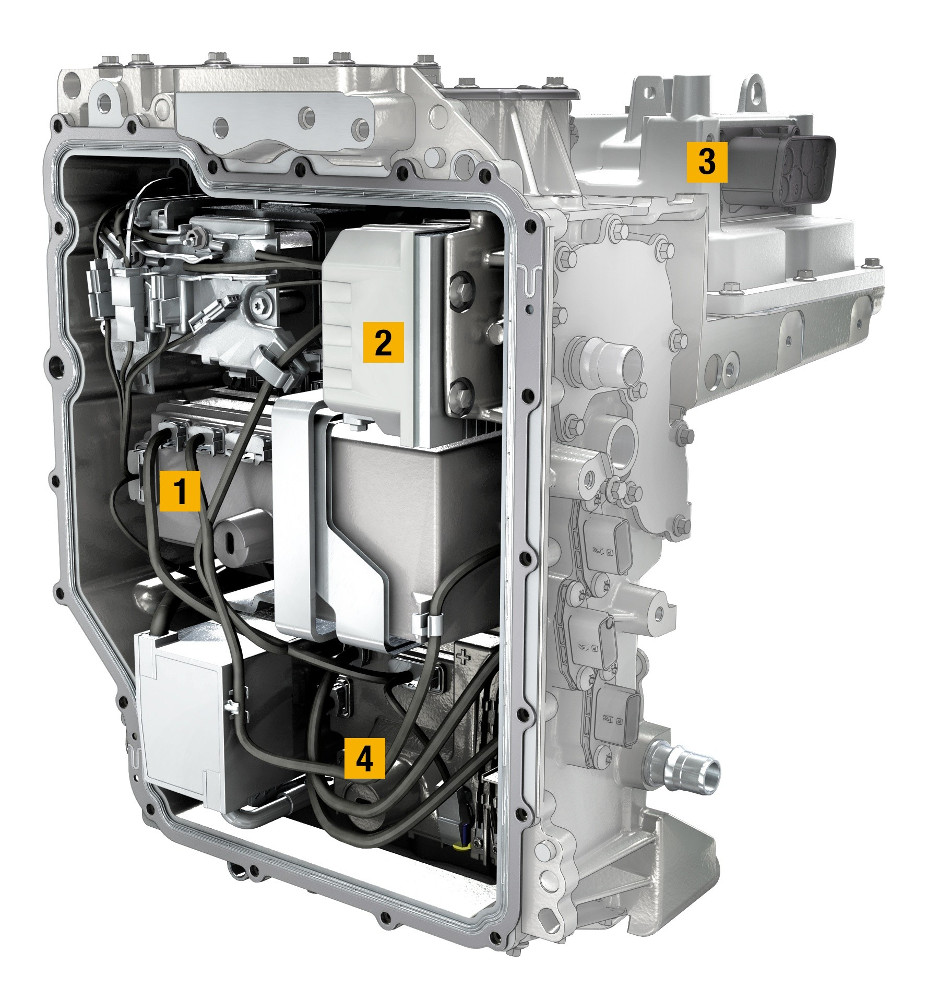

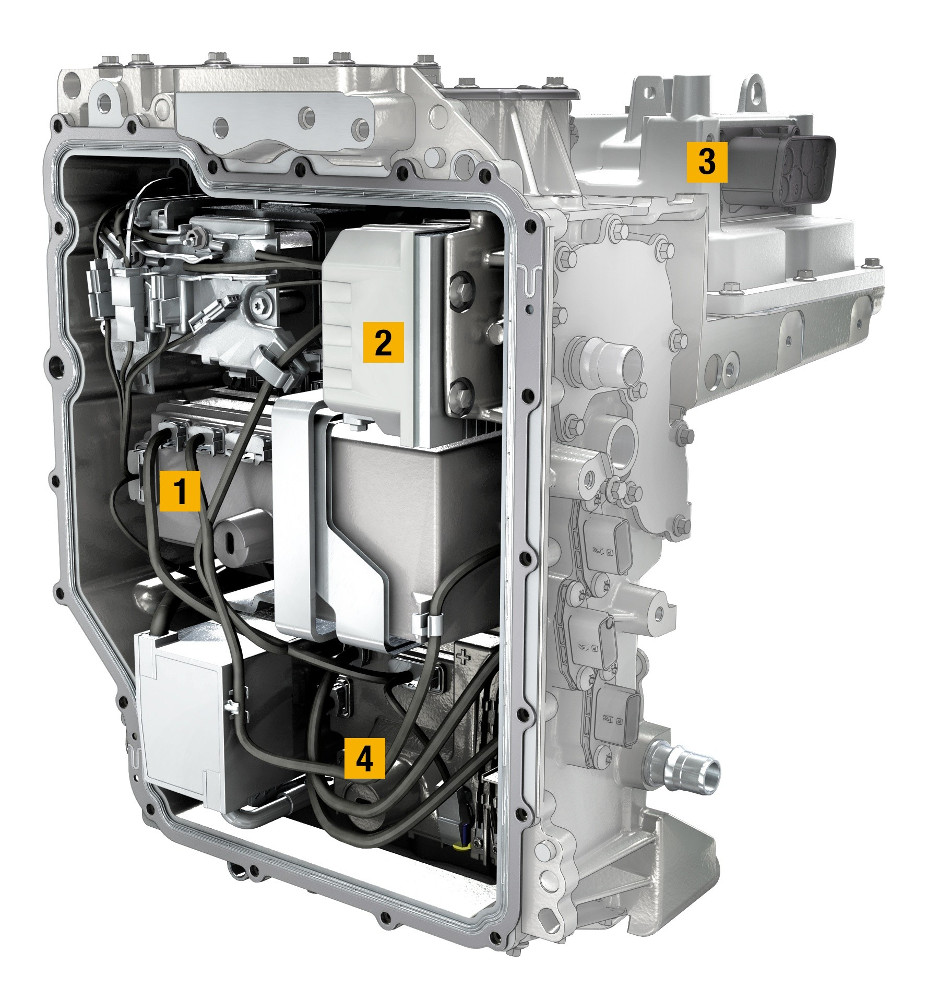

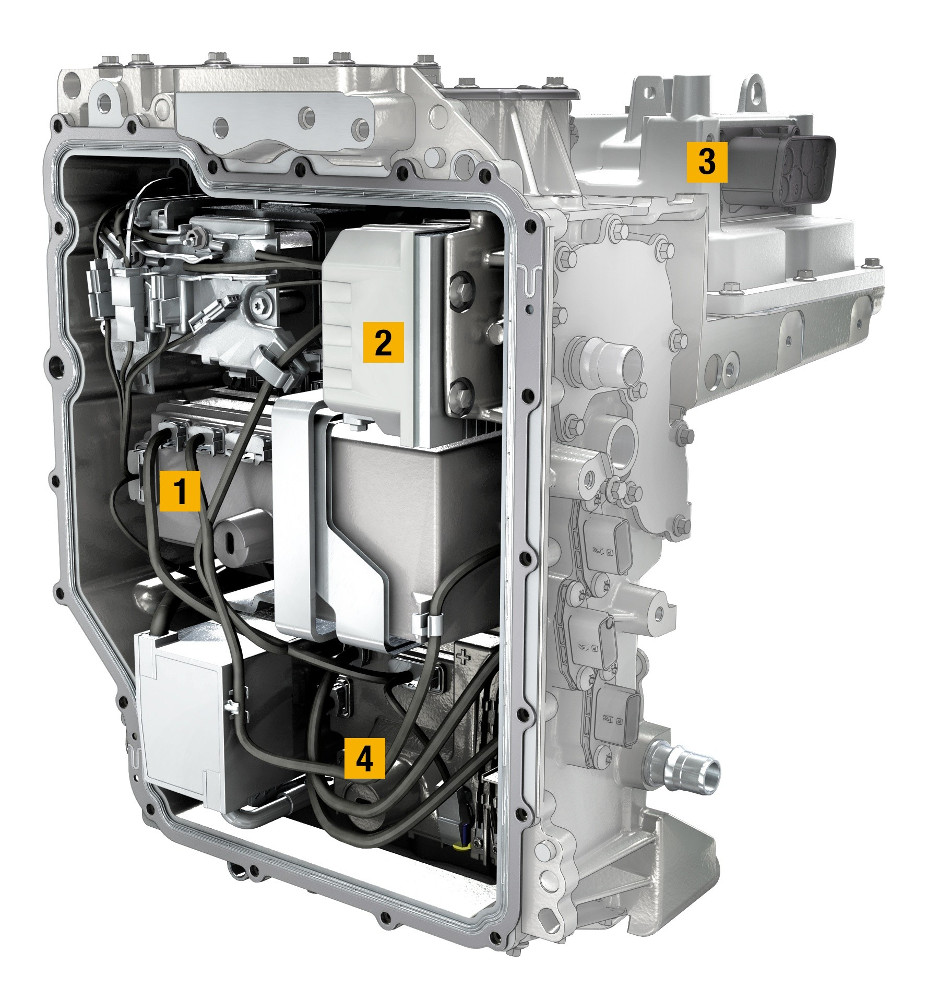

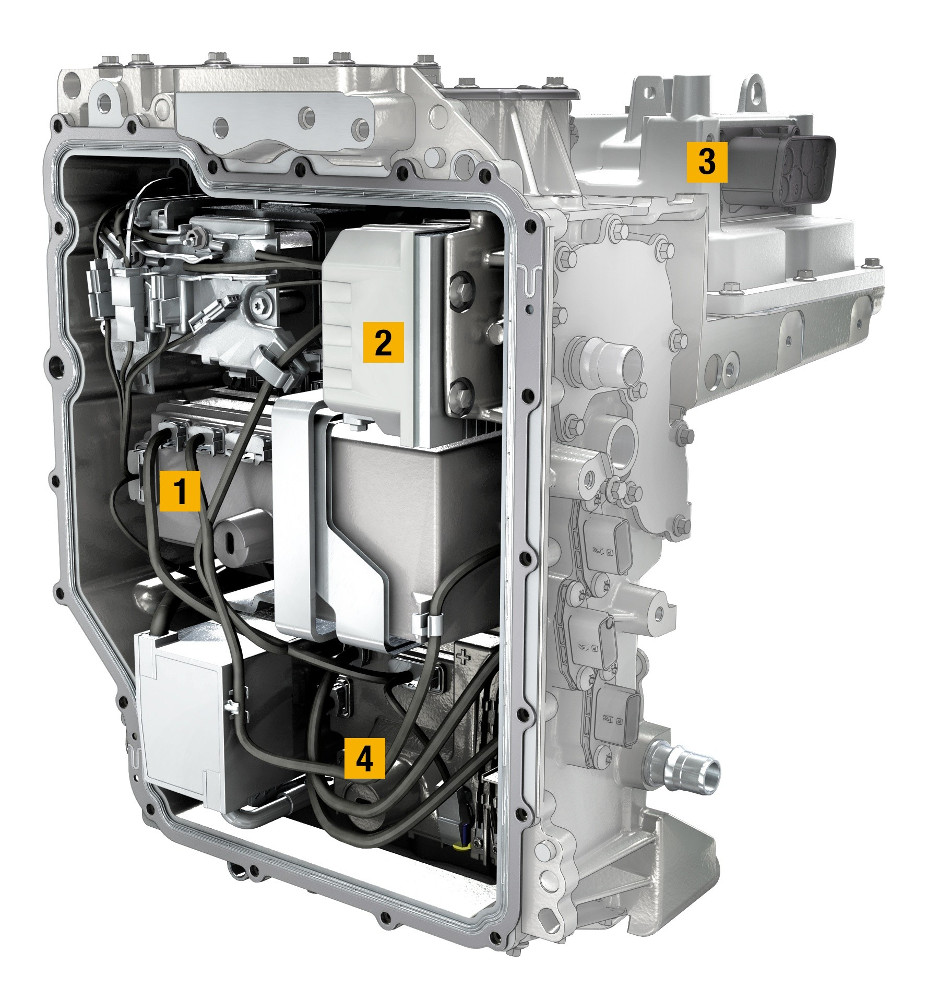

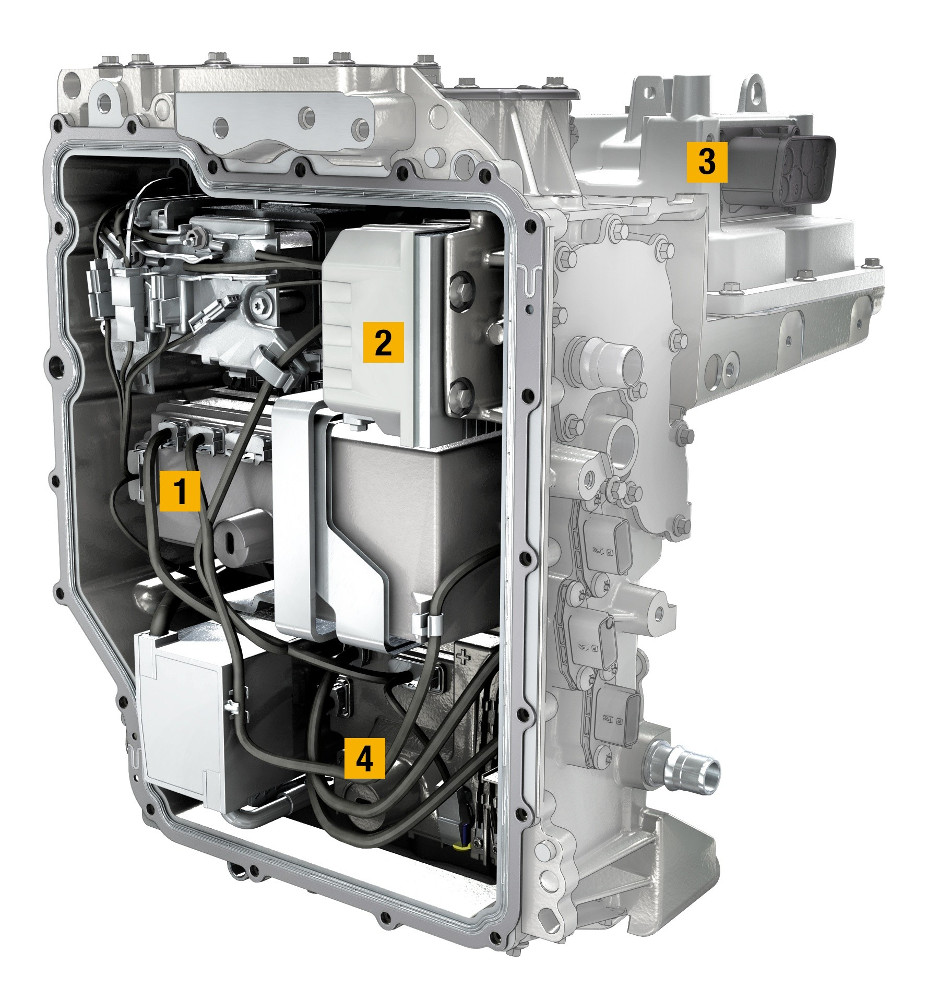

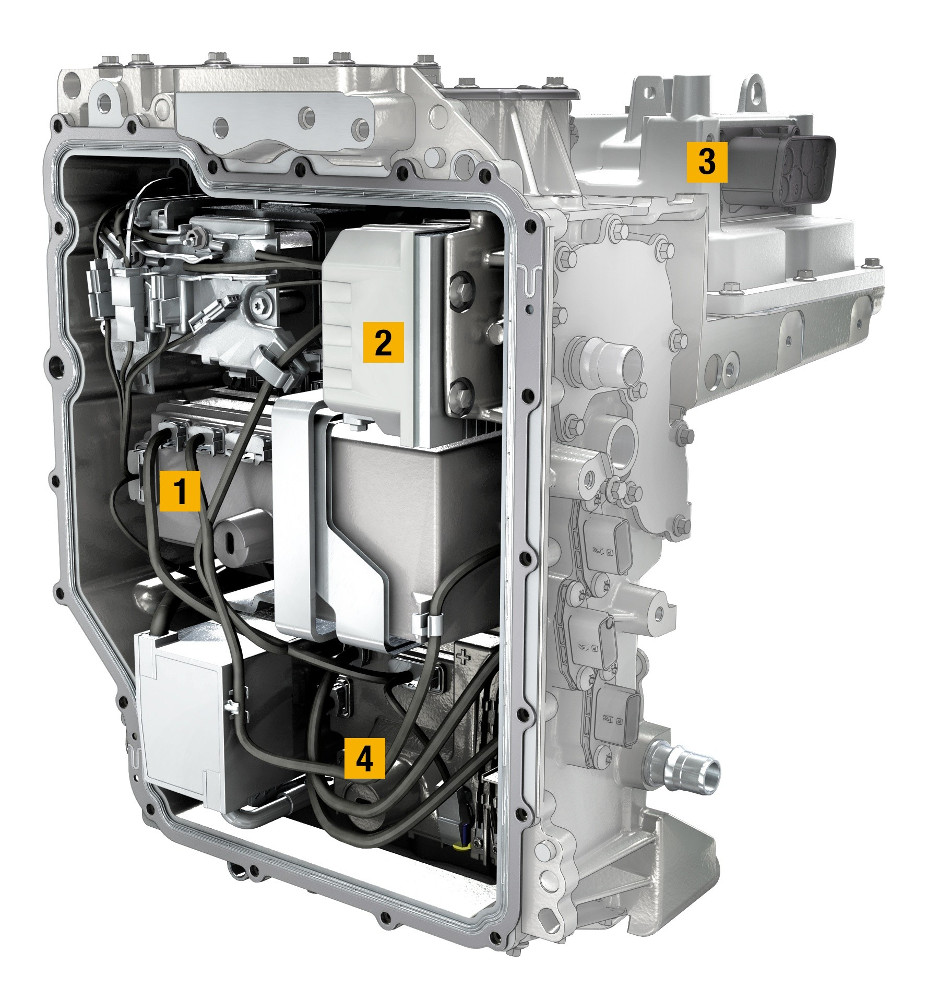

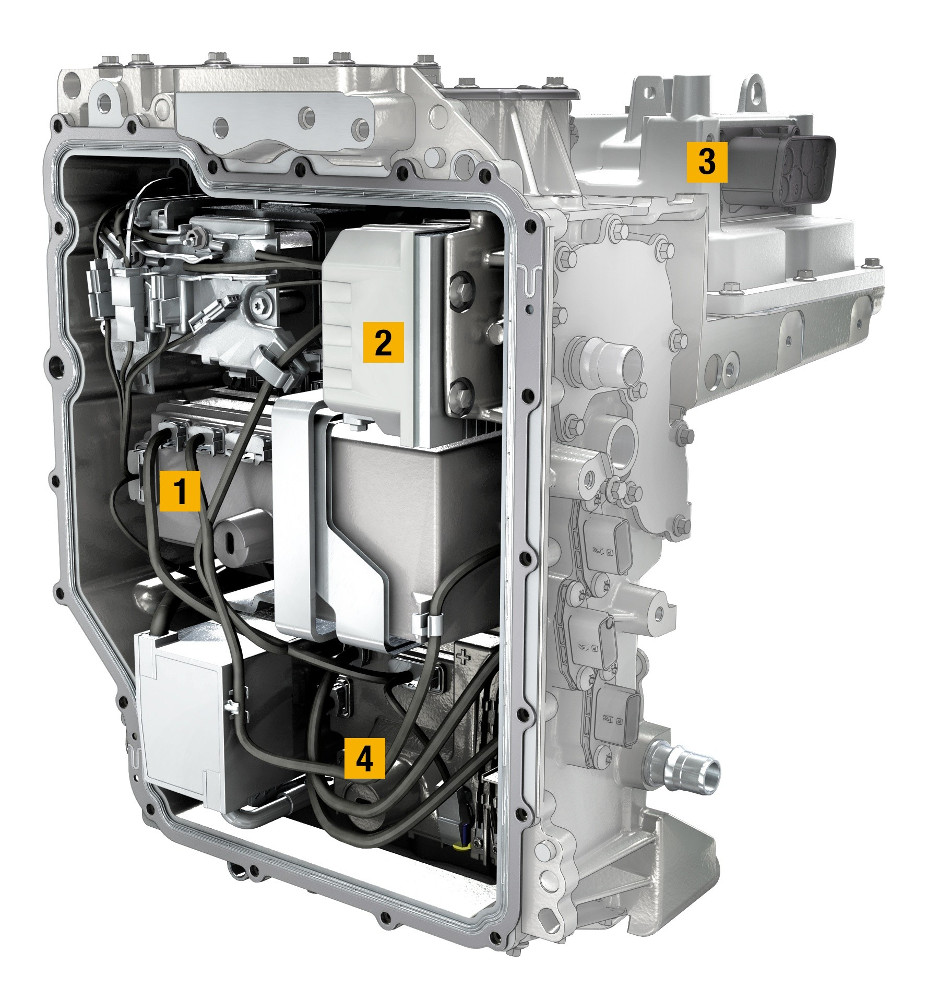

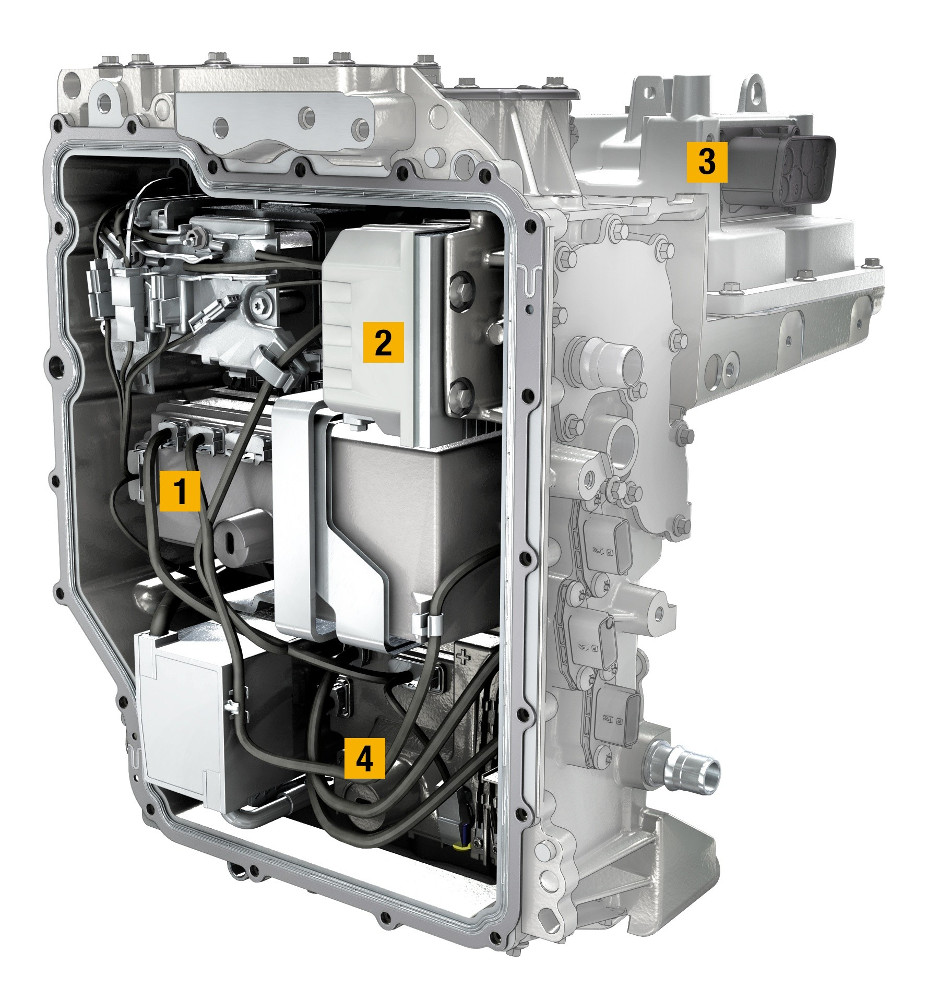

--=- *Image 4 - Renault Zoe power electronics

+ *Image 4 - Renault Zoe power electronics

Source: [Renault Cleon Plant press kit](https://www.autoblog.com/photos/renault-r250-electric-motor-at-cleon-plant/#slide-1448570)*

Looking at Image 4, we see an example Power electronic controller of an electric vehicle.

@@ -95,15 +97,15 @@ When the vehicle is charged from a home electrical grid (e.g. 220 V),

1. The **rectifier** converts the alternating current (AC) into direct current (DC), which is fed into the high voltage battery.

-2. The **DC-DC converter** is responsible with the lowering of the high voltage (e.g. 400 V) to the low voltage network (12 V).

+2. The **DC-DC converter** is responsible for the lowering of the high voltage (e.g. 400 V) to the low voltage network (12 V).

-3. The **inverter** controls the electric machine speed and torque by converting the direct current from the battery into the alternating 3-phase current for the electric machine.

+3. The **inverter** controls the electric machine's speed and torque by converting the direct current from the battery into the alternating 3-phase current for the electric machine.

4. When the vehicle is in the energy recuperation phase (braking) the inverter is doing the opposite conversion, from 3-phase AC to DC.

5. The **input filter** reduces the electric noise or interference generated during regenerative braking, when energy is fed back into the batteries via the motors.

-##S Understanding motors

+## Understanding motors

Image 3 - Schematic build-up of an automotive battery system

Let's take a look at the main component of an EV, i.e. the battery or the storage component.

->We use the word "storage component" here because electric vehicles can either be powered by batteries or via hydrogen fuel cells and both of these store energy in the vehicle.

+> We use the word "storage component" here because electric vehicles can either be powered by batteries or via hydrogen fuel cells and both of these store energy in the vehicle.

The energy storage component in a pure battery electric vehicle is the high voltage (HV) battery. The nominal voltage is, in most of the cases, between 360 and 450 V. A BEV has also a low voltage battery, the usual 12 V battery, which is used as a power supply for the auxiliary equipment (lightning, multimedia, etc.).

The battery is the key component of the EVs because:

-* The range of the vehicle depends almost entirely on the HV battery,

-* It is the heaviest electrical component,

-* It is the most expensive electrical component.

+- The range of the vehicle depends almost entirely on the HV battery.

+- It is the heaviest electrical component.

+- It is the most expensive electrical component.

- >Various types of high voltage batteries exist, with their chemistry serving as the primary distinguishing factor. Among the most common, high voltage (HV) batteries used in Battery Electric Vehicles (BEVs) are the lithium-ion batteries. Furthermore, lithium-ion batteries come in various iterations, each with its own distinctive characteristics.

+ > Various types of high voltage batteries exist, with their chemistry serving as the primary distinguishing factor. Among the most common, high voltage (HV) batteries used in Battery Electric Vehicles (BEVs) are the lithium-ion batteries. Furthermore, lithium-ion batteries come in various iterations, each with its own distinctive characteristics.

> - Metal-oxides (e.g. Lithium Manganese Oxide, LiMn2O2)

> - Phosphates (e.g. Lithium Iron Phosphate, LiFePO4)

**Usually in automotive applications, phosphate lithium-ion batteries are more suitable because they are safer in terms of chemical and thermal hazards.**

-#### The Battery Management System

+## The Battery Management System

Battery Management Systems are the brains behind battery packs. They manage the output, charging and discharging, and provide notifications on the status of the battery pack. They also provide critical safeguards to protect the batteries from damage.

A battery pack usually consists of several individual cells that work together in combination. Ideally, all the cells in a battery pack should be kept at the same state of charge. If the cells go out of balance, individual cells can get stressed and lead to premature charge termination and a reduction in the overall life of the battery.

-The cell balancers of the battery management system, extend the life of the battery by preventing this imbalance of charge in individual cells from occurring.

+The cell balancers of the battery management system, extend the life of the battery by preventing this imbalance of charge in individual cells.

The second most important function performed by a battery management system is **energy management**.

-The key to energy management is **coulomb counting.** For example, if you have 5 people in a room and 2 people leave, you're left with 3. If 3 more people enter, you now have 6 people in the room. If the room has a capacity of 10 people, with 6 people inside, the room is 60% full. A battery management system tracks this capacity. This state of charge is communicated to the user electronically through a digital bus.

+The key to energy management is **coulomb counting**. For example, if you have 5 people in a room and 2 people leave, you're left with 3. If 3 more people enter, you now have 6 people in the room. If the room has a capacity of 10 people, with 6 people inside, the room is 60% full. A battery management system tracks this capacity. This state of charge is communicated to the user electronically through a digital bus.

Battery management systems for smaller electric vehicles also include an embedded charger consisting of a control device, an inductor (which is an energy storage device), and a discharger. The control device manages the charging algorithm.

@@ -76,9 +78,9 @@ Looking at Image 3, we see the complete powertrain of an electric vehicle.

3. Rotor (Part of a motor) - *Shown in Image 5*

4. Single-speed gearbox and differential.

-# Power electronic controller

+## Power electronic controller

--=- *Image 4 - Renault Zoe power electronics

+ *Image 4 - Renault Zoe power electronics

Source: [Renault Cleon Plant press kit](https://www.autoblog.com/photos/renault-r250-electric-motor-at-cleon-plant/#slide-1448570)*

Looking at Image 4, we see an example Power electronic controller of an electric vehicle.

@@ -95,15 +97,15 @@ When the vehicle is charged from a home electrical grid (e.g. 220 V),

1. The **rectifier** converts the alternating current (AC) into direct current (DC), which is fed into the high voltage battery.

-2. The **DC-DC converter** is responsible with the lowering of the high voltage (e.g. 400 V) to the low voltage network (12 V).

+2. The **DC-DC converter** is responsible for the lowering of the high voltage (e.g. 400 V) to the low voltage network (12 V).

-3. The **inverter** controls the electric machine speed and torque by converting the direct current from the battery into the alternating 3-phase current for the electric machine.

+3. The **inverter** controls the electric machine's speed and torque by converting the direct current from the battery into the alternating 3-phase current for the electric machine.

4. When the vehicle is in the energy recuperation phase (braking) the inverter is doing the opposite conversion, from 3-phase AC to DC.

5. The **input filter** reduces the electric noise or interference generated during regenerative braking, when energy is fed back into the batteries via the motors.

-##S Understanding motors

+## Understanding motors

@@ -111,8 +113,8 @@ When the vehicle is charged from a home electrical grid (e.g. 220 V),

The torque is provided by an electric machine. In passenger vehicle applications, there are mainly two types of electric motors already in use,

-- Permanent magnet machines.

-- Inductance machines.

+- Permanent magnet machines

+- Inductance machines

It’s more appropriate to call them electric machines instead of motors because they can also generate electrical energy during vehicle braking. This mechanism is called energy recuperation/regeneration.

diff --git a/L2 Understading electric vehicless/Types of electric vehicles and their power sources.md b/L2 Understading electric vehicless/Types of electric vehicles and their power sources.md

index dd37829..f1d385d 100644

--- a/L2 Understading electric vehicless/Types of electric vehicles and their power sources.md

+++ b/L2 Understading electric vehicless/Types of electric vehicles and their power sources.md

@@ -1,12 +1,12 @@

-Having familiarized ourselves with the distinctions separating electric vehicles from internal combustion engines, let's delve into the various classifications within the space of electric vehicles.

+Having familiarised ourselves with the distinctions separating electric vehicles from internal combustion engines, let's delve into the various classifications within the space of electric vehicles.